Industries are the backbone of the world economy and global development. There are a lot of industries like manufacturing industries, IT industries, businesses, etc that consist of a lot of equipment of every standard. This is a tough task to maintain equipment as any big error in equipment can result in downtime and a decrease in efficiency and productivity. Here is a stats show that large industrial facilities lose hundreds of millions of dollars a year to machine failures.

The average cost of lost revenue, financial penalties, idle staff time, and restarting lines is $532,000 per hour.

To solve these issues, there are a lot of technologies that can be integrated to offer the incredible benefit of predictive maintenance. Generative AI is one of the greatest revolutions in the technology world that can implement different industrial operations to offer predictive maintenance.

Overview

Generative AI is transforming predictive maintenance in industrial operations by employing capable machine learning models to anticipate equipment breakdowns before they happen. With the integration of real-time IoT sensors, data can be gathered that can be analyzed using generative models such as GANs and VAEs, and predict possible failure scenarios. By predicting asset deterioration, identifying abnormalities, and optimizing maintenance plans, these models lower expenses and downtime. AI solutions can also improve decision-making and failure mode forecasts by producing synthetic data.

Predictive maintenance has been implemented by various industries and has a positive result. Predictive maintenance can save 8–12% compared to preventive maintenance, and up to 40% compared to reactive maintenance. Where the market size in the Generative AI market is projected to reach US$36.06bn in 2024. The market size is expected to show an annual growth rate (CAGR 2024-2030) of 46.47%, resulting in a market volume of US$356.10bn by 2030.

In this article, we will see the role of generative AI in enhancing predictive maintenance for industrial operations. We will see some other details like benefits and challenges.

Role of Generative AI for Predictive Maintenance

Generative AI for predictive maintenance to enhance industrial operation generally refers to using machine learning algorithms and AI frameworks to analyze operational circumstances, and assets performance about baseline data, search for failure indications, spot even negligible decreases in efficiency, and recommend repair to meet requirements before failure happens. It enables maintaining efficiency and productivity within the organization.

Also Read: Top Use Cases of Generative AI in Enhancing Customer Experience

Benefits of Generative AI for Predictive Maintenance in Industrial Operations

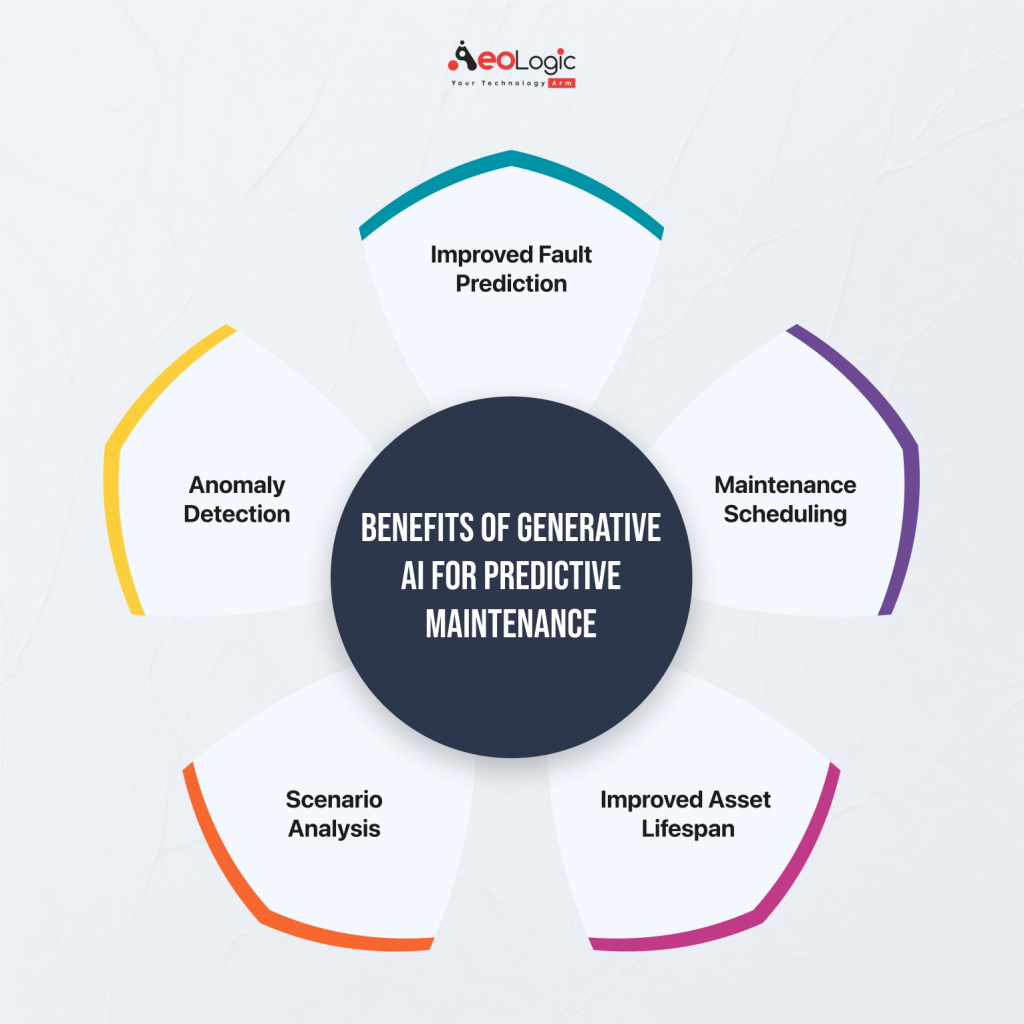

There are a lot of benefits of generative AI for predictive maintenance in industrial operations. Here are a few key benefits mentioned below.

Improved Fault Prediction and Detection

There is always historical data about the fault of equipment in industrial operations that can be used to improve fault prediction and detection for the future. With generative AI, it is possible to analyze historical data that gives organizations proper data-based insights to make predictive maintenance better than the previous one. This overall enables prevention before causing too much damage.

Enhance Maintenance Scheduling

Only maintaining industrial operation during the fault is not important but it is also important to improve timely maintenance scheduling. With manual maintenance scheduling, there is always a high chance of making miscalculations. Where with generative AI, many operations can be automated that provide more enhanced and accurate maintenance scheduling in industrial operations.

Also Read: How Generative AI Can Accelerate Software Development Delivery

Improved Asset Lifespan

Maintaining different industrial operations and assets in the same manner can be concerning. There could be many assets that are not too much damage and there can be others that are too much damage. So in this condition, both types need different manners of maintenance. With generative AI-powered predictive maintenance, maintenance can be performed based on asset conditions within a certain time interval. This overall enhances the asset lifespan than usual.

Scenario Analysis

There are various possibilities and scenarios that can affect the industrial operation and maintenance of equipment, assets, etc. With generative AI predictive maintenance, it is possible to analyze different kinds of scenarios that give a proper idea about potential risks and possible outcomes. This overall enhances the decision-making regarding the maintenance of aspects within the industry.

Anomaly Detection

There can be different kinds of risk factors that cannot be detected with the manual maintenance of aspects in industrial operations. With the generative AI-powered predictive maintenance, it is possible to analyze that help to detect any unusual pattern in operation. Soon any risk factors are detected, and the AI system makes an alert to take precautions.

Challenges with the Implementation of Generative AI

As we have seen some incredible benefits of generative AI for predictive maintenance, now it turns to focus on possible challenges with it. Here are a few mentioned below.

- Generative AI highly relies on data quality so it is necessary to have the best quality data to take accurate results. Any noise or biased data type can provide inaccurate and wrong results.

- AI is generally a black box, which means it is most complex to understand. A lack of transparency can make it difficult for users to understand and trust generative AI.

- Integration complexity can be an issue as it is quite hard to integrate generative AI into existing systems. This can result in downtime for the organizations.

Also Read: The Role of Generative AI in Predictive Analytics and Business Forecasting

Final Words

Generative AI offers a highly predictive maintenance facility for industrial operations. It enhances efficiency, v productivity within the organization. It can analyze vast amounts of data. Also, generative AI can easily detect anomalies, and equipment failure before causing too much damage.

The data-driven approach enables more precise decision-making. It can minimize maintenance costs and ensure smoother operations across various industries. Implementing generative AI involves challenges like integration complexity, initial implementation cost, etc., but the benefits are incredible and easily outweigh the challenges. The successful deployment of generative AI in predictive maintenance can revolutionize industrial operations by enhancing every aspect.