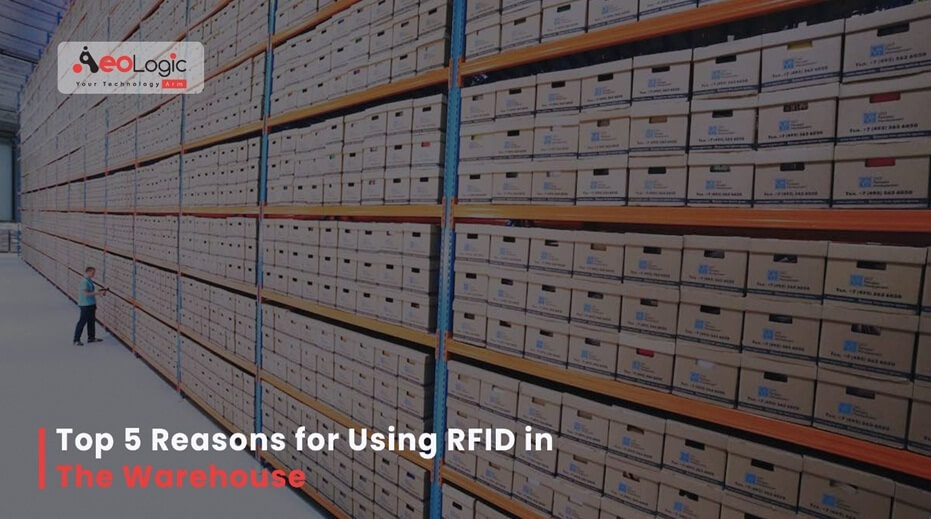

Management of inventory is very crucial to all company’s bottom lines. We have heard several times while working with the warehouse team that it is not a child’s game. The complexity in managing a warehouse is huge and sometimes beyond expectations. With best practices, we understood the core for managing inventory in a warehouse which involves understanding the flow of products, keeping track of inventory levels, and tracking what goes in and out of the building.

With many organizations running lean, tracking these elements and using them to control inventory is important for being profitable.

A recent technology that appears to be the best solution to modern warehouse inventory management is RFID technology. The technology provides a number of features that make them perfect for solving inventory management challenges.

RFID Technology Which is Being Used in Warehouses Today

RFID is required to keep track of the movements and storage of products within the warehouse and maximising the process efficiency by streamlining the inward and outward movement of goods.

To ensure that this can be achieved, passive RFID tags are mostly coming into use. Such RFID tags do not have transmitters or a power source it reflects the radio waves from the antennae back to them, giving a real-time location. It also has some internal space to store product details.

RFID Warehouse Software technology connects warehouse workers with warehouse management. The software runs on the back-end application server, where the wireless handheld devices will record warehouse activities. This includes scanning bar codes or RFID tags attached to the products. Using this realistic data, any individual can easily identify from where to pick the product, where to put it away, what is the count, or where to move products within the distribution centre.

Also Read: Benefit Analysis of RFID Library Solutions

FIVE Reasons for Using RFID in the Warehouse

1. Inventory auditing

Inventory accuracy is vitally important, obviously, there are challenge lies in achieving it. RFID technology helps to achieve and maintain 99.9% inventory accuracy without the hectic and often very expensive inventory audits. Audits take hours or sometimes days to complete which takes a hell of a lot of time and fortune to carry out. RFID provides real-time pallet location information within minutes. By accurately monitoring inventory inward outward movement, we can analyse and streamline by carrying correct stock at all times.

2. Labour management

Implementation of RFID is an effective way to increase ROI and revenue. It helps to improve inbound and outbound routing. Real-time GPS tracking provides unparalleled accuracy and the resulting in a boom in productivity and efficiency.

- Monitor staff behaviours and avoid time wastage.

- Maximise staff scheduling for correct manpower on the floor at any time.

- Reduce human error.

By creating the most optimal work routes and processes, jobs can be carries out really quick and safer than ever before.

3. Improved Shipping Efficiency

Usually, transportation is clearly responsible to make or break an otherwise successful warehousing venture. Having access to real-time driver movement, information means one can work with drivers to continuously redefine the process and improve performance that benefits both the driver and the business.

Calculating efficiencies is not as simple as it looks and without RFID technology it would be a nightmare for any company to identify where time has been spent or wasted.

Boost your business with our RFID Solutions!

Using a Warehouse Management System, provides accurate movement data, enabling clients to locate exactly where and how time is lost. This gives clients huge openness and reliability over the business and maximum customer satisfaction.

4. Workplace Safety

RFID enables positive company culture. An attitude of care towards employees is one that is both sustainable and essential for longevity and growth.

As with the help of RFID, we are tracking almost everything happening inside the warehouse, using all of the information we can avoid future accidents. As RFIS allows to investigate and avoid such problems, from determining accountability to redirecting warehouse flow ultimately helps to prevent future accidents.

5. Increase Revenue

By minimizing out of stock products, or eliminating the credibility gap, will allow the consumers to get the trend which intern increase the popularity within the market.

RFID-based companies stand strong within the market in terms of trends and stock. Companies enabled with RFID technology gets the opportunity to analyse all the data received from the warehouse which in turn converts into accurate and dependable information. This helps the company to increase its sales and revenue.