.Supply chain management is very important in every industry as it involves every process from the initial to the final preparation of products or services. There are many processes like monitoring, detecting, analyzing, maintenance, etc in the supply chain and total managing together refers to the supply chain management. Improper management of the supply chain could result in a reduction in productivity and an increase in downtime. Many processes are repetitive and easy and take labor with time. This seems not worthy in any manner as the complex process remains incomplete. It needs something technical to evolve all process processing methods that increase productivity, efficiency, and increase transparency.

Many nations have developed automation in their industry to modify the supply chain management ways. Even they had immense success in that so it is not bad to say that automation could evolve supply chain management at the global level. There is a statistic that shows that about 80% of businesses are speeding up process automation, while 50 % of them are planning to automate all repetitive tasks. It is expected that about 69 % of all managerial work will be completely automated by 2024.

Automation is not only involved in industries but there are many organizations where it has made an incredible impact. Automation has a great global market size as the Global Industrial Control and Automation market size is estimated to be USD 147.9 billion in 2022 and is projected to reach USD 218.8 billion by 2027, at a CAGR of 8.2%. This is overall quite impressive in every manner.

In this article, we will see the importance or role of automation in supply chain management and how it can evolve in managing the supply chain. We will also see other details like benefits, challenges, etc.

Also Read: Benefits of Marketing Automation You Need to Know

What is Automation in Supply Chain Management?

Automation solutions is defined as the process of using technology to complete tasks with less help from humans. Automation can be implemented in any industry that deals with repetitive operations, but it is most common in the manufacturing, robotics, and automotive industries as well as in IT systems. The use of technology to manage supply chain processes without direct human participation is known as supply chain automation. Automation employs a variety of technologies and takes many different forms.

Also Read: Why Robotic Process Automation is the Future of Business

How Automation can Enhance Supply Chain Management?

Supply chain management can evolve with automation as supply chains powered by automation tools give companies new ways to cope with uncertainty and keep business processes and products moving. It can automate the process and reduce the labor work. Automation can also detect errors that enable mandatory prevention and maintenance. Automation can also be used in terms of customers. There are many benefits and ways that automation can enhance the whole supply chain.

Benefits of Automation in Supply Chain Management

Automation can evolve supply chain management in many ways and offers a lot of benefits. Here are a few benefits mentioned below.

Improving Accuracy

Humans can make errors while processing different tasks that could result in a decrease in efficiency and productivity. Automation can reduce errors associated with manual processes, which in turn, helps plan cost control by providing accurate, real-time information on inventory levels. This overall decreases maintenance costs and also enhances efficiency.

Integration with Large Suppliers

Finding and integrating larger suppliers is one of the major aspects of business. With automation in a supply chain is the ability to link systems with those of large suppliers, since it allows for a solid foundation that allows for increased visibility amongst partners. This helps to maintain your brand value and also advertise your business.

Changing Regulations

There are many aspects like import and export limitations, health and safety laws, and quality requirements in every market you operate in, you may lose your ability to operate in that market or face steep fines. These regulations can change with automation as there will be less probability of a bad side.

Increasing Costs

Price increases across raw materials, fuel, and labor are driven by many terms like material scarcity, energy price hikes, and higher wages that have a huge impact on operating costs. Businesses are faced with passing these costs on to customers by increasing their prices or absorbing them and restricting profit margins. These overall increase the revenue generation and increase total capital.

Checkout our Trending Blog: Top 10 Guidelines for Efficient Robotic Process Automation

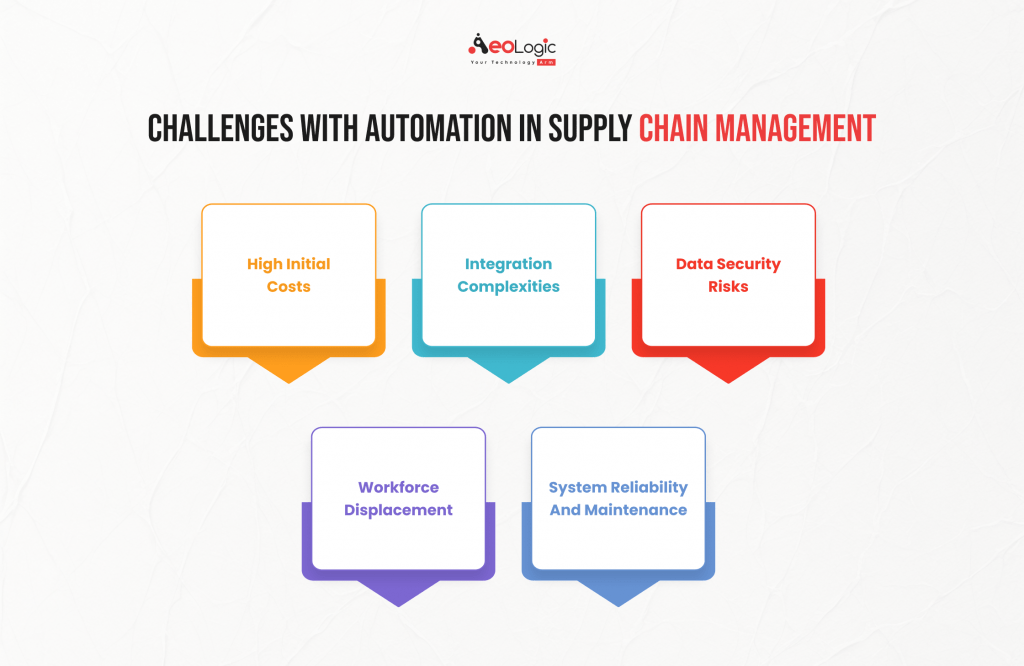

Challenges with Automation in Supply Chain Management

We have seen various benefits of automation in supply chain management but there are some challenges too. Here are a few challenges mentioned below.

- Adapting to unforeseen changes could be a challenge for many industries of automation in supply chain management. It is not quick and easy to adapt to this incredible technology.

- High initial cost also seems challenges as small industries cannot implement automation in their system for supply chain management.

- Automation has a complex interface. It is not easy to learn by businesses which could result in downtime for some time. So it could also be a challenge.

Also Read: The Benefits of Using Automation in Manufacturing

Conclusion

Supply chain management with automation provides modern ways to smooth workflows, and real-time data to help businesses as it overall enhances their operations. The majority of firms today have disjointed systems. Automation is simply the future of supply chain management as with the increasing demands and competitive edge world, it is not possible to survive a business with manual handling of supply chain processes. In the future, automation will not only be a choice, but it will be the only option for evolution.