Introduction

Supply chain management is getting more important as the movement towards worldwide sustainability kicks off, but why is traceability important for companies that want to offer good supply chain management? Traceability allows companies to precisely follow the history of where their products have been. Suppose of it like a missing package or airline bag if you are trying to figure out where your package went, would not it be helpful to know its entire history and each place it was scrutinized before it got lost in the ocean of the postal service? Let’s have glance at the importance of traceability in supply chain management.

Also read: Role of Traceability in Sustainable Supply Chain Management

What’s Traceability in Supply Chain Management?

When pertaining to supply chain management and sustainability, traceability in supply chain management refers to the capability to track and validate the history or earlier positions of processing of a product or event. Traceability generally relies on recorded data and records to insure that these different way and processes have been proved for future reference. Traceability frequently makes use of technology, similar as Radio-frequency Identification (RFID), digital barcodes, or periodical figures to track the history of a product – important like a package in conveyance. This helps to give a detailed history possible of where the product has been.

“Traceability is a conformation of two words, “trace” and “capability” – and can mean different things depending on which assiduity the term traceability is being used in. ”

What are Some of the Challenges of Enforcing Traceability?

While traceability in supply chain management is one of the effective ways to insure good supply chain operation, it does not come without its caveats. For instance, seeking to apply lesser traceability will have to retain the help of multiple stakeholders. Whereas, all of which are likely to have a different preference on how to ameliorate traceability. This means extreme concession and planning is needed to apply traceability in supply chain management across an entire supply chain. In addition to this, technology and structure could be outdated or inconsistent across suppliers, financial matters or a general lack of resources could help the proper traceability tactics from being implemented, or difficulties in communication between stakeholders could all make enforcing traceability grueling.

There are clearly numerous walls when it comes to enforcing lesser traceability within a supply chain and company. Still, this does not mean that companies cannot make the effort to ameliorate their traceability for the supply chain operation.

First, companies should seek to ameliorate their traceability in supply chain management by understanding all of the regulations they’re needed to deal with. After this necessary step is completed, companies can also develop a plan to produce a practicable plan to ameliorate their traceability. The best way for companies to successfully ameliorate their traceability is to seek third- party backing to help develop a substantiated plan on how to best digitally mark all products to encourage supply chain visibility and overall better supply chain management.

Traceability is about translucency, so anyhow if your company chooses to seek the help of a third party to ameliorate their traceability or not – it’s imperative to encourage all suppliers throughout a supply chain to expose their data, especially for stakeholders.

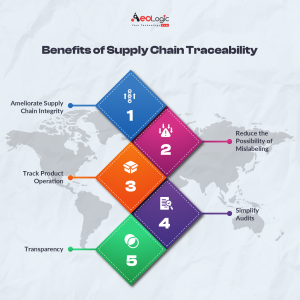

Benefits of Supply Chain Traceability

The most significant benefits of supply chain traceability are regulatory compliance and improved reputation character.

Ameliorate Supply Chain Integrity

Traceability helps in preventing fake items. And thus, makes sure of the authenticity of products. Moreover, it then helps in tracking the item throughout its entire lifecycle. That too, from raw material sourcing to the client. And further provides visibility if it’s resold, reused, reclaimed or recalled. Traceability also helps to remove supply chain backups and ensures quality, safety and a sustainable supply chain.

Reduce the Possibility of Mislabeling

Digitized labeling similar as barcodes or RFID labels contains information for tracking and tracing a product throughout its lifecycle. It helps to identify fake or defective products and assures its authenticity. This prevents the threat of mislabeling.

Track Product Operation

The traceability and tracking operation systems could be landing data within their supply chain or across a multi-supplier network able of tracking across the entire value chain.

- Traceability of processing details, for example, type and stages for producing the product.

- At each step of the product cycle traceability of quality checks is needed .

- Product manufacturing date, batch, lot, and type must be recorded and labelled consequently.

- Record where the product was transferred (forward tracking) and from where it came (backward tracing).

- The above details must be recorded using time stamping and linked to identifiers for verification and inspection purposes.

Simplify Audits

Tracking operation of a product helps at the time of inspection. The adjudicator can perform due industriousness fluently and corroborate whether the product has been sourced, manufactured and transported as per sustainability practices and established norms.

Also read: Traceability Solutions for Supply Chains with Examples

Conclusion

Associations must unite and insure information, resources and costs incurred are participated with multiple stakeholders to effectively make end- to- end visibility and traceability and foster growth and adaptability.

To know more about traceability solutions for your business, get in touch with us now!

FAQs

Why is Traceability Important in The Supply Chain?

Supply chain traceability is essential to any successful business. Because it allows companies to track products from commencement to buy. And indeed further to their end- of- life conditioning. Whether it is about reselling or reclaiming the product. It also helps ameliorate sustainability, effectiveness, adaptability and performance.

What’s Traceability in Logistics?

Traceability in logistics is the capability to pinpoint a product’s different stages from origin to the end- user. This further assists in finding the item at any time across the supply chain.

How Can Traceability be Bettered in the Supply Chain?

An association can ameliorate its supply chain traceability by digitally labeling its products. And making sure of the end- to- end supply chain visibility that helps track the product from its origin to end of life.