Data is an important factor in any industry to enhance productivity and optimization. Data-driven decisions have a high chance of proper execution and success whereas not having proper data about the industrial process can lead to loss and least success rates. Accurate insights into the industry help to streamline the supply chain management process and other logistics operations too. Data analytics can be a factor that can provide proper data insights to the manufacturing industries so that they can know about the aspects they need to work on. Here are some stats on data analytics mentioned.

The global big data analytics market is worth $307.52 billion. Cloud computing is the top technology for companies investing in data and analytics. 91.9% of organizations achieved measurable value from data and analytics investments in 2023. There are 3 of 5 organizations that use data analytics systems to increase their efficiency.

We will see more detailed information about the importance of data analytics in optimizing the manufacturing industry of the world. Also, we will see challenges faced while performing data analytics.

What is Data Analytics in Optimizing Industry?

Data analytics converts raw data into actionable insights that include a range of tools, technologies, and processes used to find trends and solve problems using data. Data analytics can shape business processes, improve decision-making, and boost business growth.

It can play an important role in the manufacturing industry by various means as it can be used for collecting, processing, and analyzing data generated throughout the production process. The main aim of using data analytics in the manufacturing industry is to improve decision-making efficiency, reduce costs, and enhance product quality. Overall it can be used to improve the whole supply chain process in the manufacturing industry which is a vital part of this industry.

Also Read: Real-Time Data Analytics in Industrial Automation through IoT

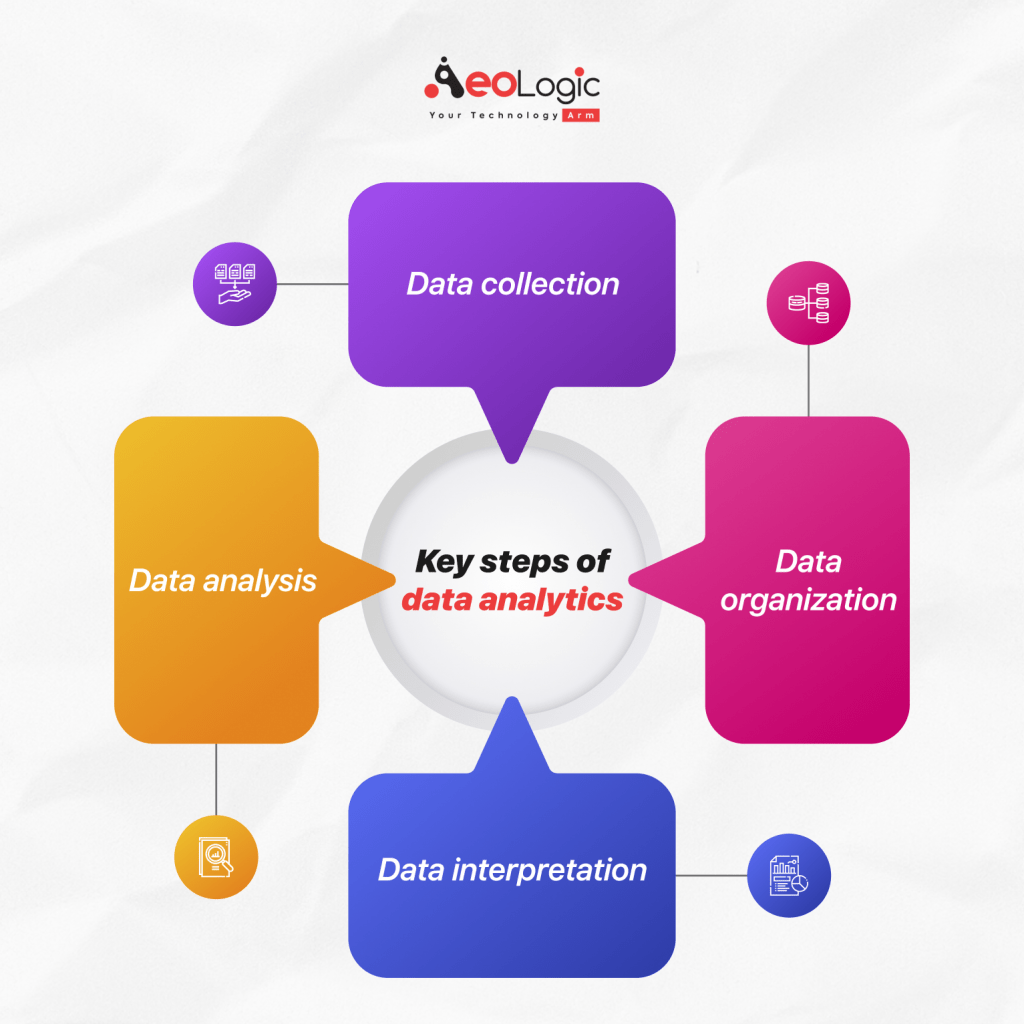

Key Steps of Data Analytics

As mentioned, data analytics refers to a process of collecting or extracting data to provide valuable insights that involve various key steps. Here are the key steps of data analytics mentioned below.

- Data collection is the primary step of data analytics as it involves collecting data via different sensor devices of the manufacturing process or from external sources such as market and customer feedback.

- Data organization is the second step which includes properly organizing data by removing errors and mistakes.

- Data analysis is the third step In this step, the organized data is examined, transformed, modeled, and interpreted to discover useful insights.

- Data interpretation is the final and important step that involves understanding the meaning of the data and drawing evidence-supported conclusions.

Also Read: The Evolution and Future of Data Science Innovation

Advantages of Data Analytics for the Manufacturing Industry

There are a lot of advantages of data analytics for the manufacturing industry as here are some of them mentioned below.

Enhanced Operational Efficiency

There are a lot of processes remaining to gather data manually as data analytics could help to cover all those hidden processes to collect data for providing valuable insights and enhancing operational efficiency. This helps manufacturers uncover hidden patterns, optimize production processes, reduce downtimes and minimize disruptions, streamline workflow, and improve resource utilization.

Improved Product Quality

In the manufacturing industry, there are always some errors occurring in product quality at different stages of production that reduce the overall product quality. Data analytics can be used to detect errors and fix details at a faster rate which improves the quality of the product.

Optimized Supply Chain Management

Data analytics enables real-time visibility into inventory levels, demand patterns, supplier performance, and other relevant information. This increases the supply chain optimization in the manufacturing industry.

Data-Driven Innovation and Product Development

Data analytics provide valuable market insights to the developer that help to develop the products. Overall it improves the ability to Identify new product opportunities and market trends and Develop innovative products that meet customer needs.

Applications of Data Analytics in the Manufacturing Industry

As there are a lot of advantages to data analytics, there are also some applications of data analytics in the manufacturing industry. Here are some of the applications mentioned below.

Predictive Maintenance

The predictive maintenance ability of data analytics provides valuable application as by leveraging data, manufacturers can perform preemptive maintenance before equipment/machine failures happen to prevent production disruption and downtime.

Demand Forecasting

Data analytics enables a strategic advantage for manufacturers by providing accurate demand forecasting. Due to manufacturers being able to predict future demand with greater precision, they can always have the right quantities of different products every time.

Root Cause Analysis

It is always difficult to find the root cause of defects manually but data analytics can provide the root cause of problems as soon as possible. This helps manufacturers to repair the fault before too much damage.

Also Read: Boost Your Business Performance With Data and Analytics

Challenges with Data Analytics in the Manufacturing Industry

If something is too good then also there are some cons. Data analytics also poses some challenges for the manufacturing industry as here are some challenges mentioned below.

- More data volume creates a complexity of data that manufacturers can’t understand properly and this could be a challenge for them.

- The use of several devices to collect data can create an overload situation and crash the system sometimes also resulting in risks to security and privacy too.

- Another data challenge refers to integrating new technologies into a company’s legacy systems such as ERPs, machine-level control systems, execution systems, and even production planning systems.

Final Words

Data analytics is an important thing that can be used to develop the manufacturing industry as this industry is one of the major industries that provides useful products to us. To enable more data, data analysts also play an important role as they know how to manage data properly. Collection, analysis, and interpretation of data have helped manufacturers make informed decisions to optimize their manufacturing workflows, improve their efficiency, and enhance product quality. Overall, a data-driven future could result in the optimization and enhancement of the manufacturing industry.