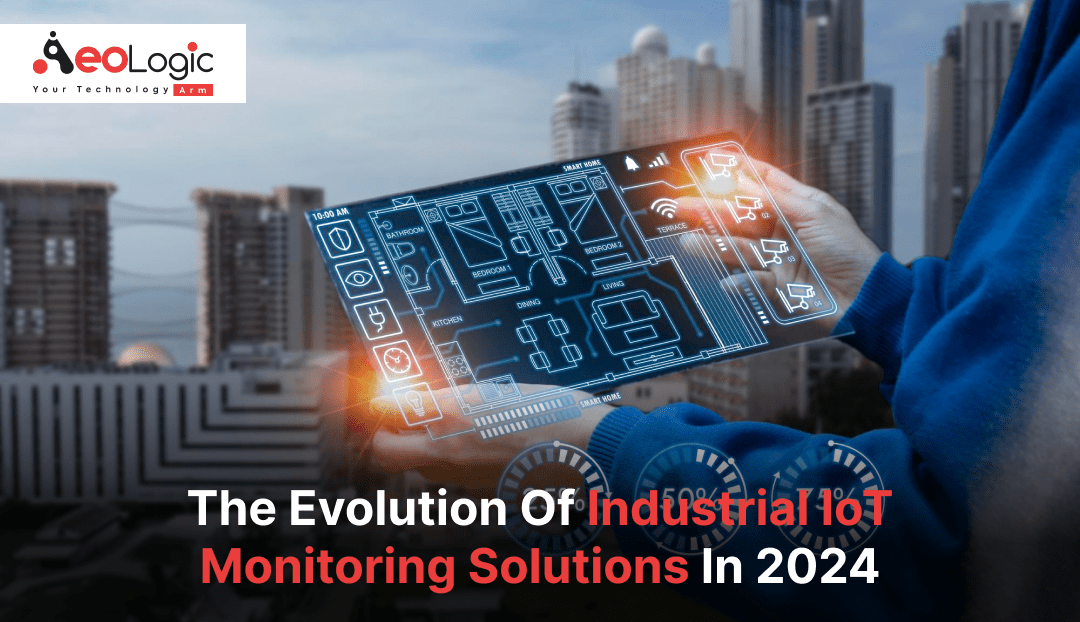

The Internet of Things (IoT) is gaining acceptance, which is helping to drive the expansion of Industrial IoT Monitoring Solutions. The Industrial IoT market worldwide is forecasted to witness a significant revenue growth, with projections indicating a staggering figure of US$238.40bn by 2024. This market segment is expected to exhibit a strong annual growth rate (CAGR 2024-2029) of 13.79%, culminating in a market volume of US$454.90bn by 2029.

This increased interest may be attributed to IoT’s ability to reduce manufacturing costs, enable remote monitoring of production, and expedite data collecting, among other benefits. As a consequence, IoT solutions use cases are becoming more common and, for certain businesses, necessary. In contrast to the promise of today’s sensor, networking, and analytics technologies, industrial IoT, or IIoT, is still in its early stages. Even though IIoT services are still in their infancy and offer certain challenges, businesses who utilize them effectively may gain a competitive advantage.

In this post, we’ll look at how beneficial Industrial IoT Monitoring Solutions are. Let’s dig in.

Overview: Industrial IoT Monitoring Solutions

The Industrial IoT Monitoring Solutions implementation starts with the installation of sensors, actuators, controllers, and human-machine interfaces. As a result, data collection is now feasible. It allows management to get objective and exact information about the status of production. The processed data is sent to all departments within the corporation. This allows employees from different departments to interact with one another and make educated choices.

The acquired data may be used to avoid unexpected downtime, equipment failures, and supply chain interruptions, enabling the business to operate more effectively.

When dealing with huge amounts of unstructured data produced by sensors, filtering and accurate interpretation are essential. So, it is necessary to communicate information in an understandable way, which is done via the use of sophisticated analytical platforms that gather, store, and assess data regarding technological processes and occurrences in real time.

The multiple use case of IoT monitoring solutions support the idea that the Industrial Internet of Things is allowing the creation of new industries that are more cost-effective, agile, and efficient than current ones. IP-enabled wireless devices, including smartphones, tablets, IoT-based parking management systems, and sensors, are already extensively utilized in manufacturing.

In the future years, wired sensor networks will be enlarged and augmented by wireless networks, considerably extending the applications for monitoring and control systems in enterprises. The next level of process optimization will be distinguished by a greater degree of convergence between the best knowledge and operational technologies.

The Value of Industrial IoT Monitoring Solutions

The industrial IoT monitoring solutions includes the discovery, assessment, monitoring, and control of connected devices. IoT monitoring can detect issues in your IoT devices that impact business and production-critical applications and services.

Every device that connects to your network uses resources, generates data, and interacts with other devices and services. Adding additional devices affects the performance of your applications, systems, and services. As a consequence, having solutions for monitoring and managing industrial IoT devices on hand is crucial for collecting high-quality data, evaluating it, creating reports, and ensuring data security.

Many industrial companies are incorporating IIoT into their operations to increase productivity by detecting and mitigating potential bottlenecks, disruptions, quality issues, and other concerns. The use of IoT in factories and plants will reduce the number of personnel, optimize resource utilization, and increase income by several times. For example, with their support in the manufacturing, you may precisely distribute orders and completely load existing equipment, minimizing downtime. Overall, the Industrial IoT Monitoring Solutions scenerio varies and may provide a variety of advantages based on the organization and the activities it is utilized for.

Also Read: IoT Solutions for Environmental Monitoring and Sustainability

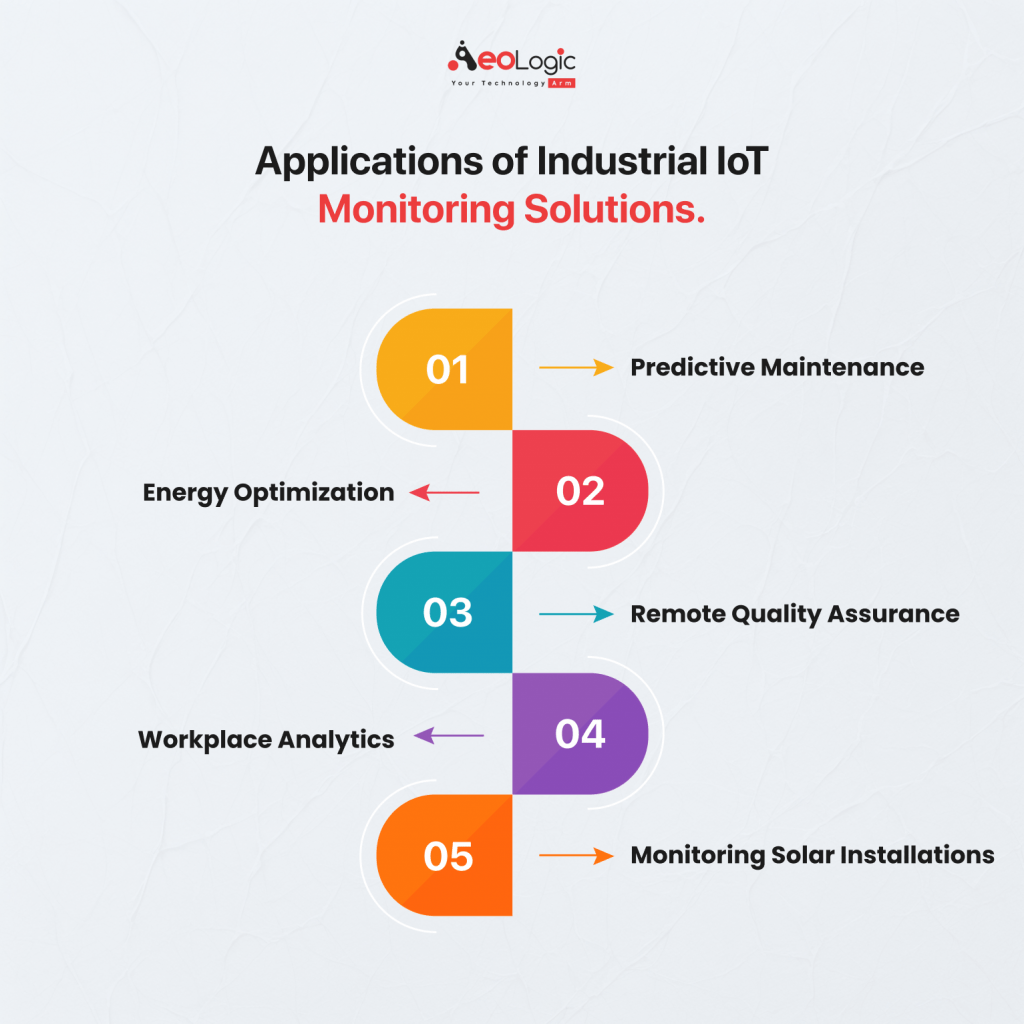

5 Applications of Industrial IoT Monitoring Solutions

Let’s have a look at the best 5 applications of Industrial IoT Monitoring Solutions:

1. Predictive Maintenance

One of the most prominent IIoT monitoring use cases is predictive maintenance, which uses wireless IIoT sensor data to anticipate and alert staff when a machine requires repair. This IIoT use case reduces costly failures and needlessly expensive maintenance while enhancing equipment availability.

Predictive maintenance saves businesses a lot of money since it reduces downtime. Any business that depends on pricey equipment, such as manufacturers, haulage companies, or construction organizations, may greatly benefit from this IoT system in business through this IIoT use case.

However, in order to reap these advantages from predictive maintenance, the analytics must have enough data. Choosing and installing the appropriate IoT devices to capture accurate data may be time-consuming and expensive. Because of these challenges, smaller facilities may struggle to adopt predictive maintenance.

For example, as part of a project, we contributed to the improvement of heat pumps. The two main issues identified were creating a user-friendly interface for remote heat pump setup and offering remote data collection and storing capabilities.

Connecting heat pumps to a third-party cloud offered a simple and cost-effective solution to all of the customer’s needs. Currently, the platform’s main feature is tools for connecting equipment, remotely receiving telemetry data, and connecting devices to a mobile application to manage their operations.

2. Optimization Of Energy Uses

Energy optimization is also one of the significant uses of industrial IoT monitoring solutions. Connecting industrial equipment, HVAC systems, and other energy-intensive devices to the Internet of Things may assist reduce energy use. IoT sensors can detect peaks and troughs in energy use and automatically adjust operations to use as little energy as possible.

While IIoT installation and certain current IoT monitoring instances have shown that the technology is successful at reducing energy use, these savings are often minimal. Without mechanical adjustments, energy efficiency can only go so far in terms of cost savings. To get considerable energy savings, businesses must build additional technologies on top of IoT sensors.

A control system for industrial greenhouses is one example of a comparable solution built by our IoT specialists. The greenhouse controller manages the heating and ventilation systems by gathering data from temperature, humidity, and carbon dioxide sensors. This not only improves the microclimate for plants, but also reduces energy costs.

Here is a controller that we used in our project and which is a simple method for converting any greenhouse into a smart one. It enables autonomous control via touch screen, as well as the integration of analog, wireless sensors, and controlled devices:

3. Quality Assurance With Remote Access

Industrial IoT sensors, including IoT-Based Water Monitoring Systems, are already being used to check the quality of resources and goods, such as water. The concept is that these sensors provide more precise and immediate information about pollution, allowing for a faster and more efficient response. Industrial enterprises that depend on quality control methods can achieve the same results by deploying IIoT technology.

Chemical manufacturers and pharmaceutical enterprises may deploy IoT devices to check the quality of raw materials and final items remotely. Remote monitoring boosts productivity by enabling staff to quickly monitor a variety of operations. Similarly, real-time alerts encourage faster reactions, reducing incidents that might threaten a product if left unchecked for a lengthy period of time.

Remote quality monitoring is a relatively new concept, thus ready-to-use solutions and services are not yet available for all use scenarios. Organizations may need to create their own IoT solutions in order to monitor the metrics that are important to them, which may be time-consuming and expensive.

Also Read: Monitoring Soil Health And Nutrient Levels With IoT Technology

4. Workplace Analytics

Organizations will have more access to process data as more industrial IoT devices are installed. Data scientists may feed the data to analytics engines that discover inefficiencies and offer methods to enhance procedures. Furthermore, location data analysis may uncover inefficiencies in warehouse organizational structure.

Many IIoT applications, like predictive maintenance, need a large amount of correct data in order to perform properly. Before these analytics to give useful and reliable insights, facilities must first establish vast IoT networks and gather data over long periods of time. They will ultimately provide a positive return on investment (ROI), but it will take time.

5. Monitoring Solar-Powered Installations

As customized solar energy solutions becomes more widely used in both home and commercial applications, it becomes more necessary to maximize the benefits of each panel. In certain circumstances, monitoring data from panels might indicate something as simple as the need for cleaning or the existence of a broken panel. Monitoring panel performance over time may help define future maintenance and replacement strategies.

Also Read: Top Benefits of Implementing a Real-Time Device Monitoring System

Final Words

Nowadays, manufacturing needs growth in the development of IoT applications and product monitoring systems. As a consequence of this progress, vast volumes of data must be handled. If producers are not prepared for this, they may soon withdraw the product from the market: without the necessary modernization, achieving competitiveness will be very difficult. That’s why they should consider industrial IoT monitoring solutions and how to implement them.

It is difficult to identify a device failure during a manual inspection before it becomes serious and shuts down the whole manufacturing line. If you are in charge of, example, the network scheduling, it is just impossible to manually verify everything. These tests should be done in a few tenths of a second interval.

As you can see, the optimum solution for the industrial sector is to use IoT, particularly in combination with a monitoring platform that employs a distributed computing strategy.

Industrial IoT monitoring solutions have a lot of potential; With Aeologic, adopting this technology may help you save money on equipment maintenance and repairs. Minor failures that cause the mechanism to fail for a lengthy period of time are often overlooked by the master. As a consequence, there will be downtime and high maintenance costs. Special sensors offer real-time information on the condition of the equipment, assisting in the prevention of malfunctions.

I’m Deepika Pandey, an SEO strategist and content writer with 6+ years of experience. I create SEO-friendly content that drives traffic and engages readers. I combine data insights with creativity to help businesses grow their online presence effectively.