There are different kinds of industries in the world that manufacture products and supply to people. This is not straightforward to develop a product as it involves various processes from initial to final that are called supply chain. It is very important to monitor the supply chain and manage it efficiently. All defects and risk factors occur in the supply chain so improper supply chain management can reduce brand reputation and product quality. Many technologies have developed to manage the supply chain efficiently and IoT is one of the best among them. IoT or the Internet of Things has many abilities like detection, integration, monitoring, etc that surely provide benefits in supply chain management.

The global IoT in the supply chain market showcased an astonishing CAGR of 15.5% from 2018 to 2022. It is projected to record a CAGR of 12.9% from 2023 to 2033. The global IoT in supply chain market size is anticipated to reach a valuation of US$ 41.8 billion by 2033. It is estimated to surpass a valuation of US$ 12.4 billion by 2023. From 2018 to 2022, the global market is projected to witness a CAGR of 15.5%. These stats are enough to make sure that IoT has been used in supply chain management for years made a big impact on supply chain management and also developed an impressive market size.

In this article, we will analyze the role and top benefits of IoT in supply chain management. Also, we will see challenges of IoT in supply chain management.

Role of IoT in Supply Chain Management

The Internet of Things, or IoT, is the collective term for the network of interconnected gadgets as well as the technology that enables communication between devices and the cloud. This technology has various features and abilities that can be used in the supply chain process using real-time monitoring technology, such as GPS, to track and trace shipments. IoT devices are also utilized for RFID tags and NFC technology in asset management. IoT devices are utilized in nearly every phase of the supply chain process overall.

Also Read: IoT in Remote Patient Monitoring: Benefits and Challenges

Why is IoT important in Supply Chain Management?

In the supply chain, many processes can cause some errors. This overall affects the product quality and decreases the productivity of the industry. It is also not easy to get data on every process without having any powerful technology. With the IoT technology solutions, the visibility of all logistics-related processes is significantly increased by continuous tracking and logging. The path and condition of items being carried are tracked at every stage, from the supplier to the consumer, to guarantee their appropriate status and on-time delivery. There are many benefits of IoT that we will see later.

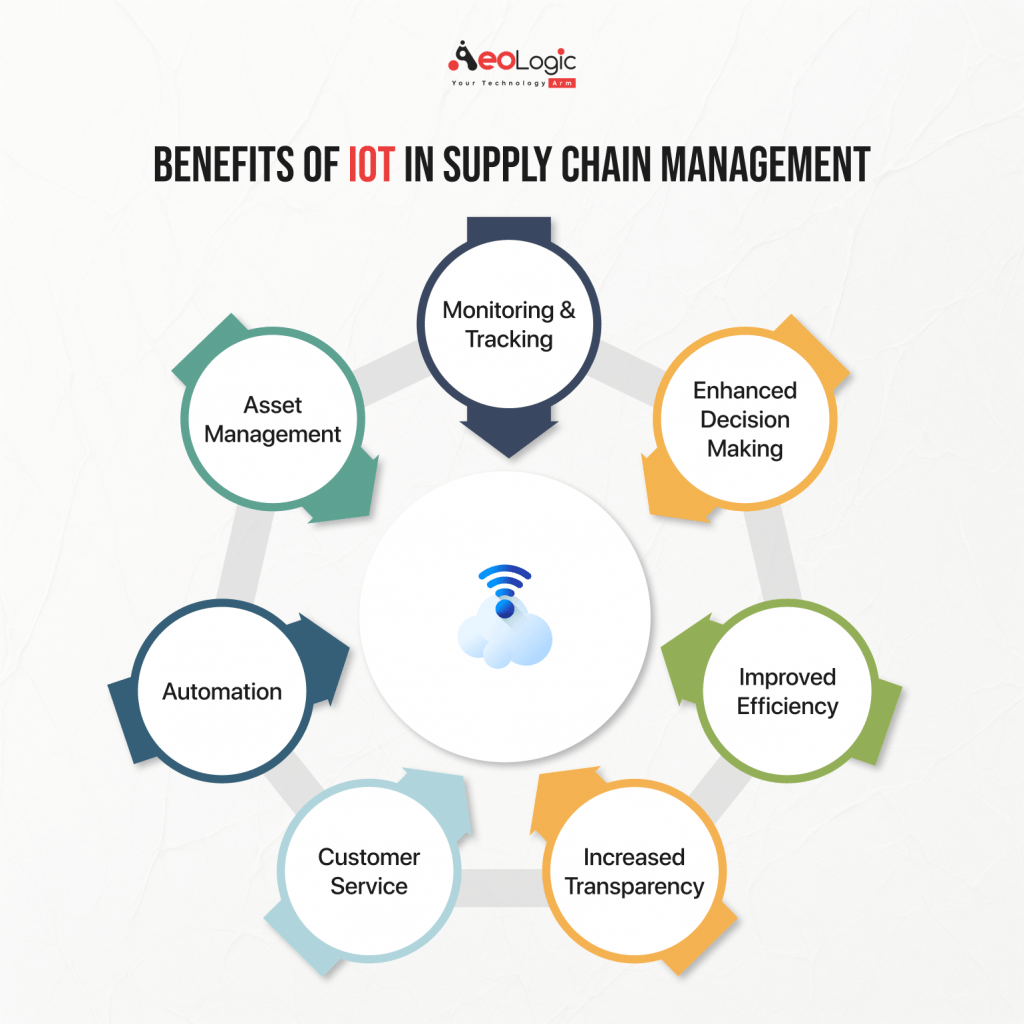

Benefits of IoT in Supply Chain Management

IoT or the Internet of Things in supply chain management offers a lot of benefits as there are a few benefits mentioned below.

1. Monitoring & Tracking

The most valuable benefits of Internet of Things solutions is their capacity to gather, transmit, and analyze data in real time utilizing specialized sensors. Because you receive data directly and instantly, these positive aspects make the supply chain and transportation of goods easy to manage and handle. IoT solutions in supply chain management allow experts to swiftly analyze product availability and condition, respond to changes in order status, and so on.

2. Enhanced Decision Making

Decision-making in any industry is very important for efficient supply chain management. With the IoT or Internet of Things, it is possible to link devices and sensors, real-time data collecting, analysis, and decision-making are made possible, converting conventional supply chains into more intelligent, responsive systems. Impressive access to every aspect of the supply chain, from production to delivery, is made possible by this revolutionary technology.

3. Improved Efficiency

Many repetitive processes in the supply chain take a lot of labor and time. Because of this, many complex tasks cannot be processed. But with the IoT, automation can be enabled in companies that can decrease human labor and streamline processes by using it to automate supply chain functions like inventory management and maintenance scheduling. This overall increases the efficiency.

4. Increased Transparency

Transparency is a very important aspect in any industry that builds trust among the partners. With the IoT technology, managers can instantly see product status. They can locate shipments precisely, anticipate possible delays, and take preventative action to deal with any problems. It is possible to follow the flow of commodities across the whole supply chain, from manufacture to delivery which enhances accountability and foster’s partner confidence.

5. Customer Service

Customer satisfaction is important as it builds their trust in the organization and product quality. However, it is not possible to strengthen the weak points without proper feedback from customers. With the IoT technology, it is possible to collect customer input and identify service improvement opportunities. Using this information could result in increased customer satisfaction.

6. Automation

Modern companies rely extensively on automation solutions to reduce the amount of physical labor necessary, labor costs, the danger of human error, the speed with which resources are supplied, and a variety of other factors. IoT enables the supply chain for manufacturing and automating this area of management and industrial processes. Drones can be utilized as IoT tools for warehouse management, or you can create a full infrastructure that can be controlled remotely to monitor logistics status.

7. Asset Management

The Internet of Things (IoT) can be used to track and manage assets. Managers no longer need to rely on manual data entry or traditional inventory devices to keep track of all assets; instead, software can do it automatically. Connected technology, such as sensors, RFID tags, beacons, and smart materials, allows supply chain managers to immediately access critical delivery information, such as package contents and storage instructions.

8. Enhanced CRM

Logistics software and Internet of Things supply chains benefit customers and management and are key applications of IoT in logistics. A number of companies use the benefits of IoT in logistics and provide specific customer-facing apps to their customers so they can track the delivery of their goods using GPS and view the status of their purchases. It helps to develop trust and handle completed order accounts when consumers can track the delivery progress of their goods to their houses.

Also Read: Exploring The Role Of IoT In Smart Mobility Solutions

Challenges with IoT in Supply Chain Management

We have seen the top benefits of IoT in supply chain management but there are also some challenges too. Here are a few challenges mentioned below.

- Data storage can be issued as IoT provides a continuous flow of data from the supply chain. This could be difficult to store data on cloud storage and sometimes it could be a data overload situation.

- The initial implementation cost is too much which could be difficult to afford for many industries. So it is also a challenge for many.

- Employee training is also a challenge as in the manufacturing industry, the employees are not habitual or trained in IoT technology. So it could take some time and cost to train employees to work on it.

Also Read: The Power of IoT in Retail to Optimize Your Business

Conclusion

In an industry, profitability may be enhanced, expenses can be decreased, and customer satisfaction can rise with a properly run inventory system with the involvement of IoT technology. Learning the art of inventory management becomes critical in the dynamic corporate environment, where supply chains experience disruptions and client demands change frequently that need to be solved. IoT has the potential to change the face of supply chain management in different industries overall increasing productivity and enhancing efficiency. IoT is still in its developing phase and many more features have to be unlocked in the future. Every organization should implement the IoT to enhance the present and secure the upcoming future.

I’m Deepika Pandey, an SEO strategist and content writer with 6+ years of experience. I create SEO-friendly content that drives traffic and engages readers. I combine data insights with creativity to help businesses grow their online presence effectively.