The manufacturing industry is one of the major industries of the world that supplies products of need. This industry has an important contribution to the world GDP as the manufacturing industry’s expected market size in 2024 could be US$79.86tn and a CAGR of 14.86% for the 2024-2028 time period.

These stats show the importance of the manufacturing industry for the whole globe. However, manufacturers face many problems in the production of products and inventory management is one of them. Simple Inventory management is responsible for ordering and tracking stock as it arrives at the warehouse. It is one of the major parts of production as improper inventory management could lead to a big loss for the industry.

Many manufacturing companies are facing issues related to inventory management as poor inventory management results in a loss in sales and a decrease in revenue. However, there is a technology that can solve various problems of inventory management in the manufacturing sector. RFID or Radio Frequency Identification is a technology that can cure these problems. We will see in detail about the RFID tags and how they can contribute to inventory management for the manufacturing industry.

Also read: How to Integrate RFID With Inventory Management

Role of RFID Technology for Inventory Management

Technically, RFID or Radio-frequency identification uses electromagnetic fields to automatically identify and track tags attached to objects. An RFID system consists of a tiny radio transponder, a radio receiver, and a transmitter.

Overall, RFID is a type of automatic identification and data collection (AIDC) technology as it collects data by radio waves and tracks items through the supply chain. RFID can be installed in scan devices and can also provide a unique identification ID as a barcode or any other code.

Inventory management with RFID tags can be used to track the whole inventory process of the manufacturing industry. It enables the collection of data on each point that could be beneficial to catch any wrong steps that make the whole management poor.

Read our trending blog: Using RFID for Inventory Management: Pros and Cons

Top Features of RFID Tags

Inventory management with RFID tags offers many features that make it a better choice in the manufacturing industry. Here are some features mentioned below.

Ability to detect hidden objects: RFID technology has a feature to track hidden objects as objects do not need to be in direct sight of the scanner. Since the detection of hidden objects also depends on the environment and surface material.

Automatic recognition: Scan readers can be installed anywhere in the way of scanning as they can automatically scan the code with the RFID tags that reduce labor and also save time by providing accuracy in the work.

A unique ID: RFID provides a unique identification ID to specific materials that each material’s information can easily access by scanning their unique ID. This is an incredible feature as this makes it easy to get information about each material in seconds.

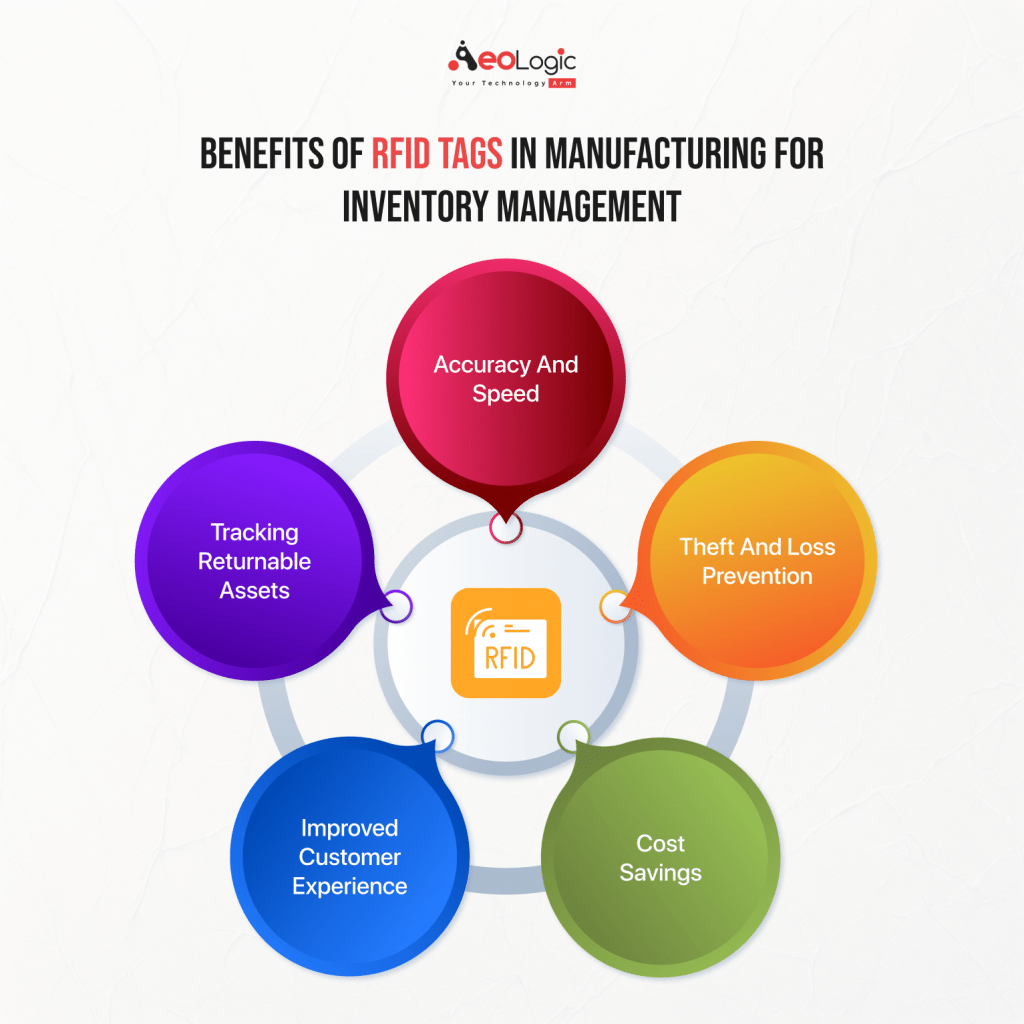

Benefits of RFID Tags in Manufacturing for Inventory Management

As it has some useful features, it offers a lot of benefits in the inventory management aspect of the manufacturing industry. Here are some of the benefits mentioned below.

Accuracy and Speed in inventory management

With the RFID tags, there could be lower error rates, and also the supply chain will become faster than before as it can automate data accurately and immediately.

Theft and Loss Prevention

RFID also plays an important role in company loss as it can soon detect that product is stolen and the nature of real-time product tracking makes it easy to identify potential supply chain issues, allowing corrective action to be taken promptly.

Cost Savings

RFID in the manufacturing industry provides an advantage in inventory management and helps industries across the board reduce costs by optimizing stock levels thus boosting profit margins.

With less error rate, accuracy and other benefits of RFID increases profitability and saves money.

Improved Customer Experience

Products are guaranteed to be available to clients when they need them thanks to accurate and current inventory information. RFID also makes it possible for staff members to find things in stores more quickly, which enhances consumer happiness and service.

Tracking Returnable Assets

For companies that depend on a fleet of returnable assets like containers and pallets, safeguarding their significant capital investment is crucial. By leveraging RFID technology, you can effectively monitor the movement of these assets throughout the entire supply chain, resulting in enhanced visibility regarding inventory whereabouts. This also has the advantage of enhancing returns and mitigating theft or negligence.

Related: RFID for Asset Tracking and Inventory Management

How Much Does the Installation of an RFID Inventory Management System Cost?

Since there are a lot of costs to take into account, figuring out how much an RFID system will cost overall might be difficult. The equipment—which can include readers, cabling, and antennas—often has the highest upfront cost.

When you include the cost of cabling and other necessary expenses like power over Ethernet (POE), passive RFID reader systems can range from approximately $1000 to $3000 per device. Due to their often lower complexity and sophistication, active reader systems can have equipment costs that are roughly ten times less than those of passive systems. Installation, asset management software, and facility alterations may incur additional upfront expenditures, which differ significantly depending on the specific circumstances. Maintenance, licence fees, and tags are all ongoing expenses associated with an RFID system. The low cost of tags is one of the long-term advantages of running a passive RFID system. RFID tags that are passive only cost between 5 and 15 cents per chip; however, tags that have special housings, like those that shield them from interference from metal objects, may cost more. Due to their more complex housing design and need for a local power supply, active RFID tags are often 100 times more expensive than passive ones, ranging from $5 to $15 per tag.

Also have a look at: Revolutionizing Inventory Management with RFID in Retail

How Has RFID Technology Changed Over the Last 20 Years?

RFID technology is not as new as you may think as it has a long past and also made a development due to successful research and development, the average cost of an RFID tag has decreased by 80% over the last ten years and the cost of a reader has decreased by 50%. With a four-fold increase in range and a two-fold increase in read accuracy, businesses like Walmart can get better outcomes with fewer readers. Inventory tracking is one of the most useful use cases of the RFID technology as it helps to streamline inventory management, accelerate picking and packing, deliver on time, etc. This could be still the initial stage of the RFID new era and in the future, it can be more powerful than ever.

Companies using RFID Tag Technology for their Inventory Management

As we mentioned RFID tag technology is not new even though many top manufacturing companies around the world are using it for their inventory management.

Tesla is one of the biggest manufacturing companies that introduced an NFC RFID key card designed to unlock and start the Tesla Model X.

Walmart is the biggest retailer in the world, so when they chose to mandate RFID tags on incoming pallets of products in 2006, While the initial RFID implementation was deployed to create supply chain visibility in a select number of products and stores.

Disney is also an example that has implemented RFID tags technology for access control in their on-site hotels while simultaneously introducing tap-to-pay features in park retail locations.

Read our related blog: Importance of RFID Technology in Library Management

RFID Tag Challenges in Manufacturing Inventory Management

Here are some challenges mentioned with RFID tags that could be faced while using them for inventory management in the manufacturing industry.

- High cost is a challenge for manufacturers as implementation costs of RFID tags can be significantly higher than continuing to use barcodes.

- It is also necessary to upgrade equipment with time and this takes a lot of time and money that stops production.

- RFID tag technology is still incompatible in many countries as their manufacturers cannot use it so it could be a challenge for you if you are thinking of implementing RFID in your industry.

Conclusion

There is not any doubt that RFID is a great technology that developed in recent years. When it comes to inventory visibility, RFID technology outperforms traditional solutions and ways. Businesses can track specific items using the unique identification on each tag, providing thorough stock management and lowering the possibility of stockouts or overstocking. This upgrades the flow of inventory management process in the manufacturing industry and this is not only beneficial for the individual as the whole globe could get benefits of RFID tag technology by implementing it in the manufacturing industry. But as mentioned still it is incompatible for many so still need to make manufacturers aware and hope that soon it will be accessible for all.