Effective inventory management is a critical aspect of any business irrespective of its size. This helps you to keep the correct products in stock at the time when your customers need them and thereby, it leads to increased customer satisfaction and higher profits. Radio Frequency Identification (RFID), for example, is one potent tool for enhancing your inventory management process. In this blog, we will discuss how to integrate RFID in inventory management.

What Is RFID in Inventory Management?

To better understand the integration of RFID with inventory management, it is important to know what the term RFID means. It is the abbreviation for Radio Frequency Identification. Radio frequency identification, or RFID, is a technology of using radio waves in the identification and tracking of objects. RFID in inventory management refers to attaching small RFID tags or labels to your products. RFID readers can read unique identification numbers present in these tags.

The use of RFID in inventory management enhances accuracy and efficiency that is impossible to achieve by traditional practices such as manual counting or the use of barcodes in tracking the inventory. DMS offers your transparent inventory tracking capabilities that enable wise decision-making and help eliminate stockout at all times.

Also Read: Benefits of RFID in Asset Tracking Management for the Navy

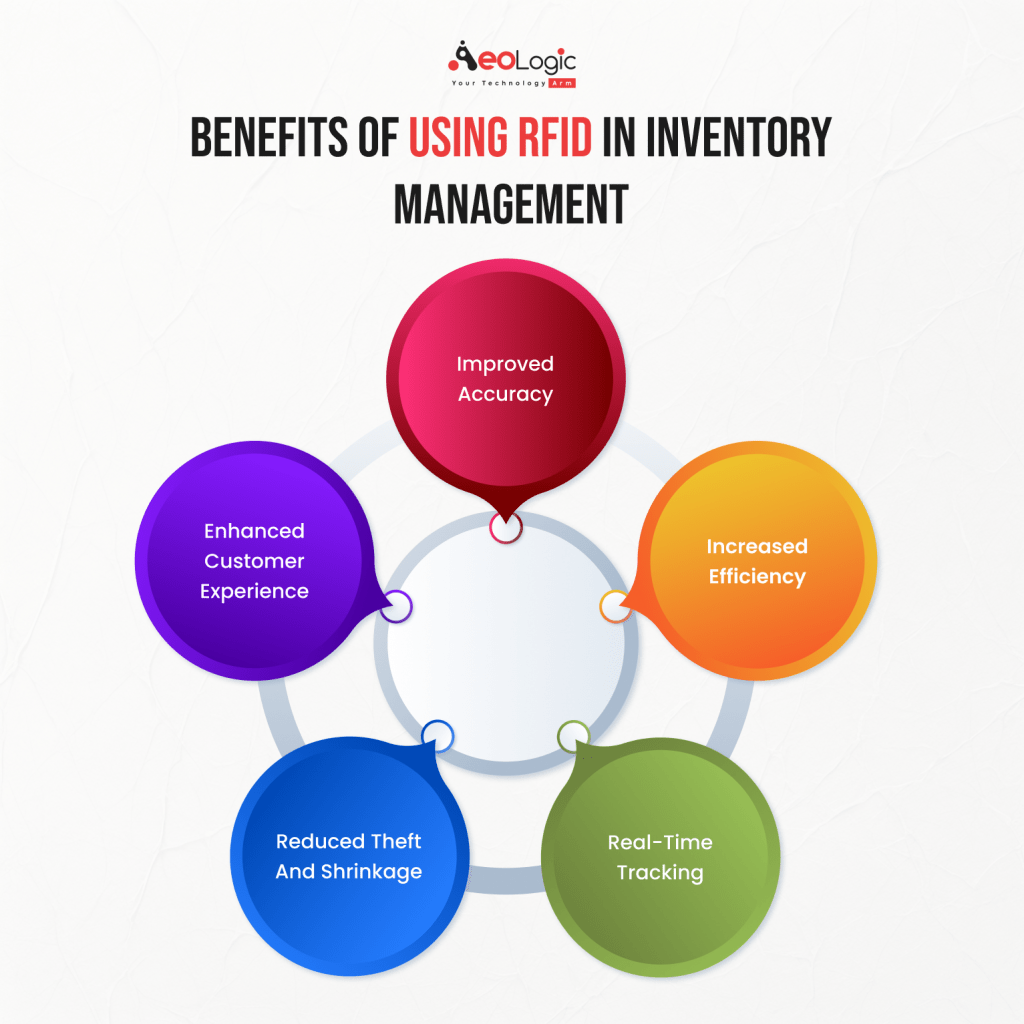

Benefits of Using RFID in Inventory Management

Having known what RFID is, we can now look at the benefits of integrating this technology in your inventory system.

1. Improved Accuracy

They also emphasise the precision of RFID in inventory management. RFID tags are a sightless tag which implies that you do not have to actually see the tags in order to read them. This minimizes human errors that can occur while counting items manually or while scanning the barcodes.

2. Increased Efficiency

RFID technology is incredibly efficient. RFID readers enable you to scan numerous items at a go, resulting in speed. As a result, you can do your inventory counts significantly faster than traditional ways and in the course of it save up on time and labor costs.

3. Real-Time Tracking

You can thus have the inventory monitored in real-time with the help of RFID. With it, you can know how many of which product are in your store or warehouse at any given time. With this visibility into what is happening on the ground in real time, they can make such decisions as ordering more stock when it is running low or redistributing products to meet demand.

4. Reduced Theft and Shrinkage

RFID tags also serve to deter theft and shrinkage because they are hard to tamper with or remove without being discovered. As a result, you will realize reduced losses from theft or mishandling of inventory, leading to cost savings in the long run.

5. Enhanced Customer Experience

Central among them is that RFID has a potential of enhancing the customer experience as well. It will enable you to offer precise stock status to customers on physical or online stores based on real-time inventory information. This minimizes the chances of customers getting disappointed with items that have become out stock.

Also Read: How RFID Tagging Solutions for Ammunition Will Help the Soldiers

How to Integrate RFID With Inventory Management

Let’s now discuss the process of integrating RFID technology into your current inventory management system after understanding the advantages of RFID in inventory management.

1. Assess Your Needs: You need to first consider your inventory management needs before implementing RFID. These include the Amount of your Inventory, Types of Products you sell and your Financial Budget. This assessment will allow you to come up with the size and breadth of the RFID undertaking.

2. Choose the Right RFID Tags: It is essential to choose the right RFID tags. There are different types of tags you can go for depending on your needs and preferences. One type of tags is meant to be used on clothes while others are for tracking pallet or large equipment. Make a point of selecting tags that are applicable to your products and place of business.

3. Purchase of RFID Readers and Antennas: You will require RFID readers and antennas to read the RFID tags on your products. These may be in the form of a handheld device or fixed reader. It depends on the purpose of use. You will also require your strategic placement of your RFID antennas for optimal tag detection in the facility.

4. Integrate RFID Software: Utilizing RFID solutions in inventory management will require specialized software that can make sense of the data read by the various RFID readers. Other than that, this software will help you in controlling your stock, keeping item records, and producing logs. Make sure the chosen software is compatible with your RFID hardware, and integrates well with an existing inventory management system.

5. Train Your Staff: Additionally, implementing RFID technology necessitates training employees in the usage of the RFID readers, software and general system. Your team must be comfortable with the new technology and know how it helps them in day-to-day.

6. Pilot Test the System: Test RFID in a small section of the warehouse/store before full integration into your inventory management. This enables you to note any problems or conditions and modify them before deploying the technology more extensively.

7. Scale Up Gradually: As you are happy with your pilot test results, the expand of RFID application can be lead gradually in all stages of your inventory management. The risk of disruptions is also minimized since the shift is gradual.

Do you know? Benefit Analysis of RFID Library Solutions

Challenges and Considerations

However, it should be noted that the introduction of RFID with inventory management faces some challenges and a number of other complications.

1. Initial Costs: The original investment in RFID technology, the tags, readers and corresponding software can be quite expensive. Nevertheless, one needs to consider this cost against the potential long-term savings and efficiency.

2. Compatibility: Make sure that your current inventory management system is RFID technology ready, or budget for a new system, or modification of the existing one.

3. Tag Placement: Placement of the RFID tags is vital. Tags should be affixed to products such that they can be easily scanned and not hidden by other objects.

4. Privacy and Security: However, if you apply it to high-value or sensitive items, such as works of art and museum artefacts, think over the privacy and security provisions. Use security practices to prevent unauthorized access to RFID data.

5. Maintenance and Support: Regular maintenance of the RFID equipment is critical in guaranteeing reliable performance. Moreover, in the event of any issues or questions, having reliable technical support is also crucial.

Final Words

Integrating RFID in your inventory management can significantly improve your ability to control and take note of your inventory accurately and precisely. RFID is useful in businesses of all sizes because of its potential benefits in terms of improved accuracy, increased efficiency, real-time tracking, theft reduction, and better customer experiences. With The challenges and considerations noted, you can therefore follow the steps in this article for successful implementation.