Managing and locating important means is a crucial challenge for nearly any business. Time spent searching for critical outfit can lead to precious delays or down time, missed deadlines and client commitments, and wasted labor. Companies have traditionally addressed this problem by managing means using periodical figures and spreadsheets, or tracking outfit with barcode markers. Nonetheless, both of these styles bear a significant quantum of manual labor. Integrate RFID tags in any tracking application with the help of this guide.

Also read: RFID for Asset Tracking and Inventory Management

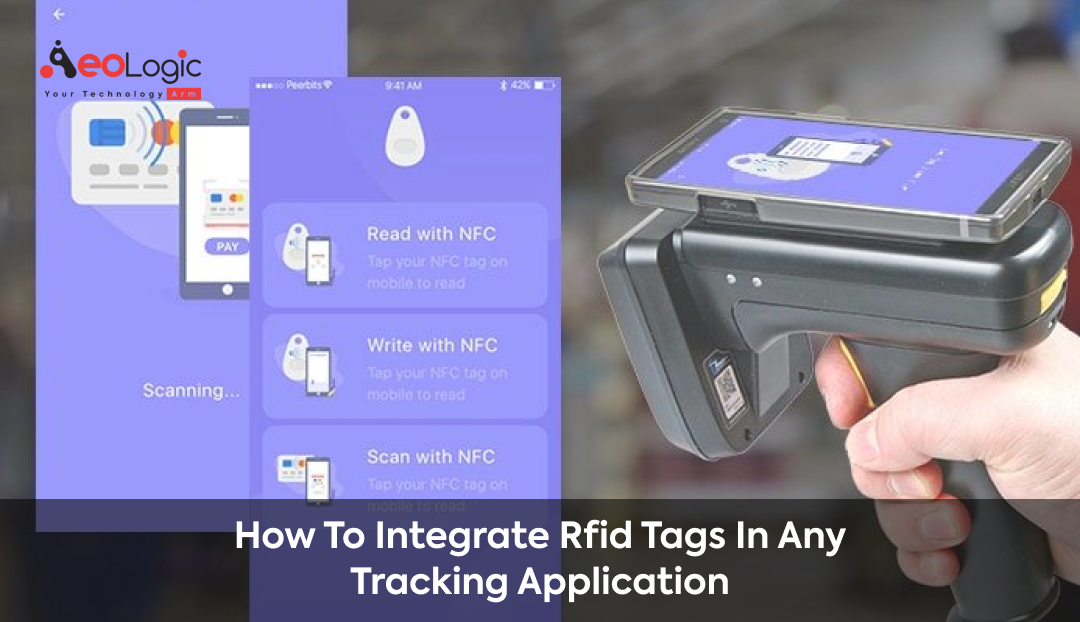

Integrate RFID Tags in Any Tracking Application

One way to quickly ameliorate asset operation is by exercising radio frequency identification (RFID) technology to automatically track those means. An RFID asset tracking system uses electromagnetic fields to transmit data from an RFID label to a reader. Whether you are talking about office outfit in a multi-story structure, wheelchairs and IV pumps in a large hospital, tools and outfit in a plant, or pumping outfit in far- flung oil fields, RFID can give accurate, real- time tracking data for fixed and mobile means.

RFID Tags: Active and Passive

There are two general categories of RFID tags, that is, active and passive. The type of RFID label you choose depends on what you want to negotiate and the type of capabilities you’re looking for. RFID markers can be active or passive.

The active RFID markers have their own power source, which can extend the signal range. It also limits their lives. The passive RFID markers are power by the transceiver’s RF signal, which enables long life, and the label can be much lower, having shrunk to just an antenna and a single- chip integrated circuit. It also reduces their read/ write signal effective distance.

Selection and Operation

To integrate RFID tags in any tracking application is to select and implement the operation. When opting an RFID system there are numerous choices. From cost, frequency and seeing range to data storehouse and read/ write capabilities, too numerous choices and contending norms or lack of norms has been an issue in the history. Check out the RFID merchandisers, but make your decision grounded on the operation and standard products. Cost is a big factor. Until the cost of RFID matches the cost of a barcode, the barcode will be a better choice in numerous operations.

With U.S. manufacturing jobs going overseas to save a many cents, adding $0.10 or much further to the cost of a product by adding an RFID label is tough to justify.

How Does RFID Asset Tracking Work?

Anyhow of the assiduity used, the introductory principles of how an RFID tracking system workshop are the same. RFID markers are physically attached to your precious means. RFID compendiums are acclimatized to your business terrain and strategically placed to ‘read’ the signals transferred by RFID markers. They are transmitted to our RFID asset tracking software and the data is reused. An intuitive user interface allows you to track and find specific means from a laptop on point, ever through your web cyber surfer or indeed on the go with your mobile device. The factors of the system are as follows

- RFID markers (passive, active or semi-passive)

- One antenna

- RFID reader

- A computer database equipped with RFID asset tracking software

RFID asset tracking process

- Data is stored in an RFID label with a unique electronic product code and attached to an asset

- An antenna identifies the signal from a near RFID label

- An RFID reader connects wirelessly to the antenna and receives data stored on the RFID label.

- The RFID reader also transmits the data to an RFID asset tracking database where it’s stored, estimated and reused.

RFID Readers

It uses internal antennas to emit radio waves to retrieve signals from RFID markers (or, connects wirelessly to the antenna to admit information in more complex systems). Readers are generally mobile, which means users can take them anywhere, but they can also be mounted (e.g. on a tall pole that allows them to see a large part of a storehouse). RFID readers estimate information in real time and can transmit the data to a software system where it’s stored and substantiated as demanded.

Definition of RFID Tags

RFID tags are a type of RFID asset tracking system that uses intelligent barcodes to identify particulars. RFID markers use radio frequency technology. These radio waves transmit data from the label to a reader and also the information to an RFID computer programme. An RFID label can also be called an RFID chip. RFID markers are attached to each asset and continuously transmit data to an antenna (integrated or separate from the reader). RFID markers can store a wealth of information, from a single periodical number to storage of associated data ranging from date of manufacture, condition and temperature to periodical number, position, movements and storehouse conditions. Anything that’s important to the organisation and can be digitised can be loaded onto a label for processing.

Also read: RFID Tracking Solutions for Asset Location and Management

Work Smarter With the RFID Asset Tracking System

RFID isn’t only popular in asset operation, but is also taking control of hand performance. The new passive RFID enabled system is designed to cover employee attendance, productivity, workflow and further. For illustration, you can measure the time it takes a handyperson to repair a service tool.

You can achieve this by using RFID grounded employee badges. The RFID performance tracking system can be seamlessly integrated with the RFID asset tracking system and increase the overall effectiveness of your business. Investing in a versatile RFID asset tracking technology system allows you to work smarter and take control of your means, workflows and workers.

Connect with us to know more about RFID Solutions.