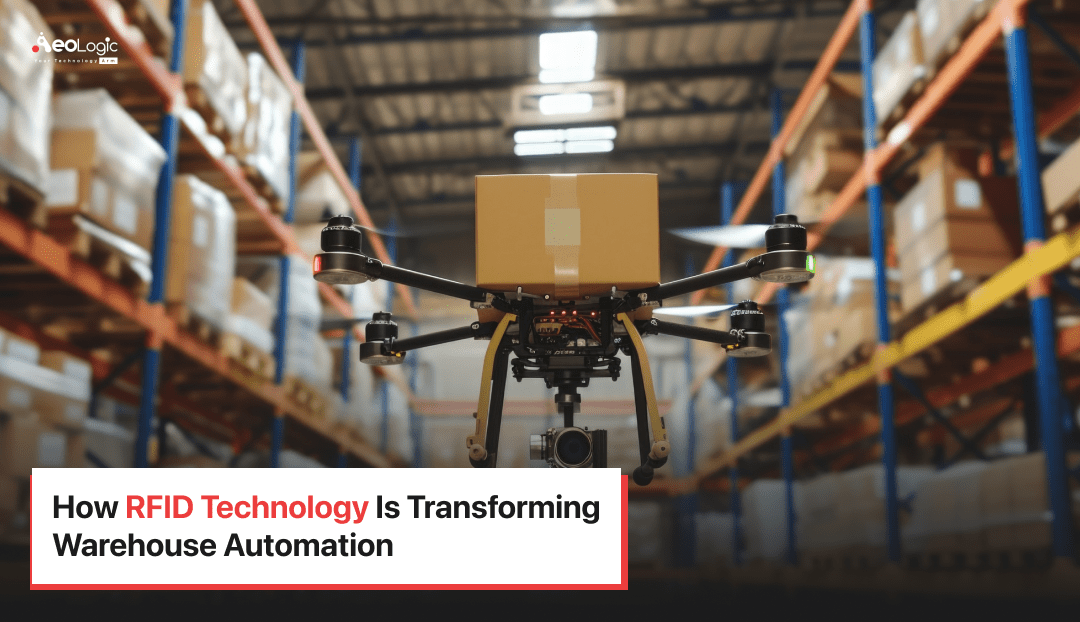

RFID is a technology that uses radio waves to automatically identify objects. In warehouses, RFID systems are used to track and manage inventory without needing direct line-of-sight scanning like barcodes. Warehouse automation with RFID has big benefits. Research shows RFID can improve inventory accuracy from 63% to 95%. It also cuts inventory count times by 96%, letting staff check up to 20,000 items an hour.

RFID consists of tags and readers. They communicate with each other to send data in real time. This technology is rapidly transforming warehouse automation and making it more efficient.

In a warehouse, RFID can automate the tracking of goods from the moment they arrive until they are shipped out. It is one of the innovative way today to see how businesses run their warehouses. RFID solutions for warehouse automation are helping. It improves accuracy and productivity.

The Role of RFID in Warehouse Automation

RFID solutions for warehouse automation serve as the backbone for modern warehouse operations. With RFID, you can automate many tasks. You can track inventory and complete your order fulfillment. It allows you to know where every item is at any given moment. It reduces the need for manual checks.

For example, when new stock arrives, RFID tags placed on items are immediately scanned and logged into the system. This helps reduce the manual labor. Items are tracked as they move through different stages of the warehouse. From receiving to storage to picking and shipping it makes everything easy. You can save time and reduce costs with the help of RFID solutions.

It helps you to ensure that inventory is always accurate. Also, leading you to fewer stockouts and overstock situations. This makes your warehouse more efficient and improves the customer experience.

Also Read: The Importance of RFID Warehouse Management System

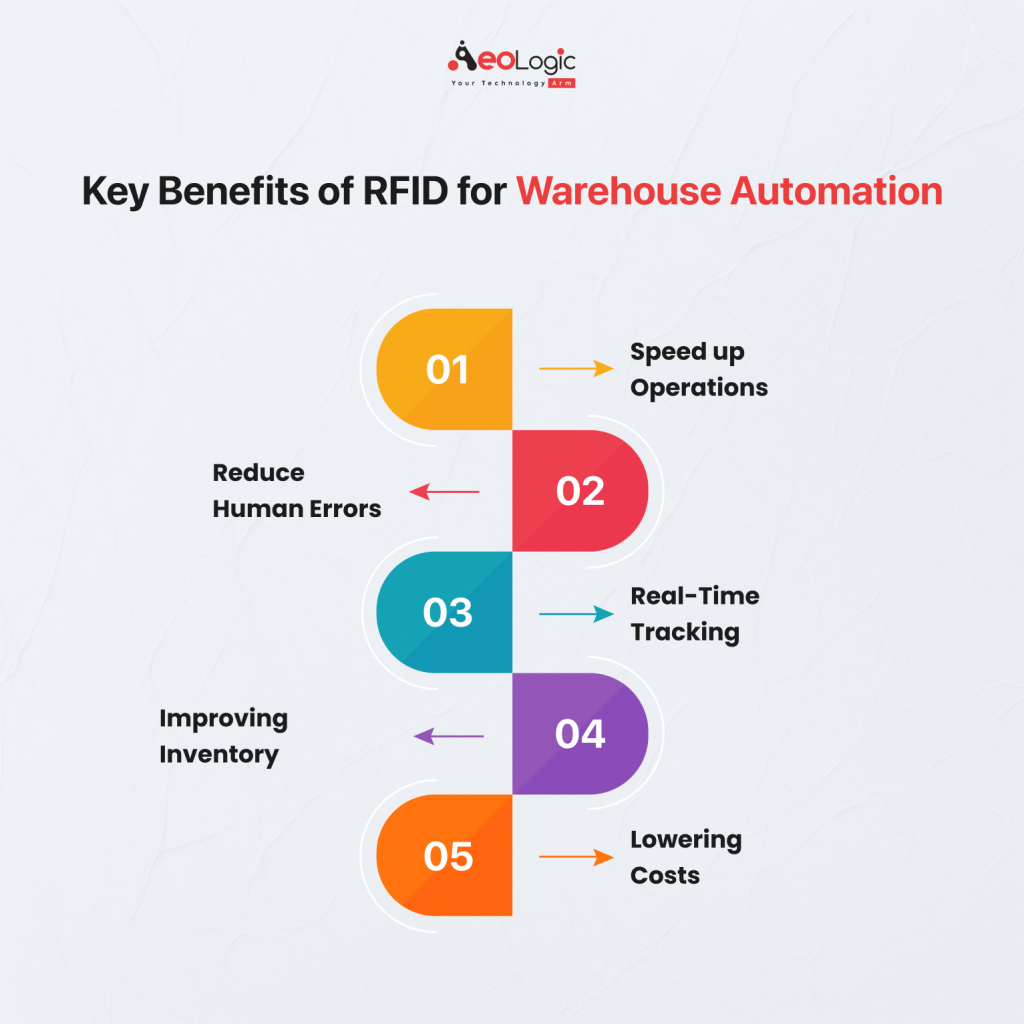

Key Benefits of RFID for Warehouse Automation

Here are the major benefits that RFID solutions for warehouse automation bring to the table:

Speeding up Operations

RFID helps automate manual tasks like inventory stock movements. RFID readers can scan many tags at once. This helps workers find products fast and update inventory. Speed is important in busy warehouses where time matters.

Reducing Human Errors

Manual work often leads to mistakes. RFID technology helps reduce these errors. It keeps inventory accurate. RFID tracks products automatically. You don’t have to worry about missed scans or wrong data.

Companies that use RFID in their warehouses can save time on operations such as inventory receiving, shipping, cycle counts, put-away, return management, and many other workflows. RFID automation frees up labour and time for other parts of your operations while reducing human error caused by manual warehouse chores.

Enhancing Real-Time Tracking

It gives you real-time updates about your inventory. You can track every item location in warehouse. Thus, this improves accuracy of your company. As you know where your goods are without having to search for them manually.

Improving Inventory Management

RFID helps automate stocktaking. It keeps your inventory always up-to-date. RFID tags provide accurate data. It makes managing stock easier. You can see your trending item like which items sell the most. Then, you can adjust stock levels to match.

Lowering Operational Costs

Implementing RFID solutions requires an initial investment. However, the savings in the long run make it worthwhile. It reduces the need for manual work, improves inventory accuracy, and speeds up operations. This helps lower warehouse costs.

Also Read: RFID Solutions for Inventory Tracking in Your Warehouse

How RFID Works in Warehouse Automation

RFID works through three main components. They are

- RFID tags,

- RFID readers, and an

- RFID system.

Here is a basic rundown of how it works:

- RFID Tags: These are small electronic devices attached to products. It contain information such as product details or stock levels. Also, stored in a microchip inside the tag.

- RFID Readers: It send out radio waves to detect and read the information stored in RFID tags. Once the tag is within range, the reader can pick up the data and send it to the inventory management system.

- RFID System: It collects and processes the data received from the RFID readers. This information is then used to track inventory. Also helps to monitor stock levels and update warehouse records.

An example of RFID in action: Suppose a warehouse with thousands of items. When a new batch of products arrives workers put RFID tags on each one. As they move the products around the warehouse RFID readers update the product’s location automatically.

Also Read: Streamline Warehouse Operations With RFID Asset Tracking

Challenges in Implementing RFID Solutions for Warehouse Automation

While RFID solutions for warehouse automation are beneficial, implementing it can come with challenges:

Initial Setup Costs: Implementing an RFID system can be expensive. You need to buy RFID tags, readers, and an appropriate management system. The long-term benefits are usually greater than the first cost.

Integration with Existing Systems: If your warehouse is using an old system, like barcodes or manual tracking, switching to RFID might take time. You need to make sure the new RFID system works with your current system.

Training Staff on the Technology: Your employees will need training to use it. They must learn how to handle RFID tags. They also need to know how to use the readers and enter the data.

Real-World Examples of RFID Solutions for Warehouse Automation

Many companies are already using RFID solutions. We can see Zara, the popular clothing retailer. They uses RFID to improve inventory management. They using it to speeding up stocktaking and making it easier to track items in real time. RFID helps them ensure that products are available when customers need them.

Another example is Amazon, which uses RFID to streamline its fulfillment process. With RFID tags on products, Amazon can quickly locate and pick items. This leads to faster shipping and fewer errors. It is now helping to improve customer satisfaction.

Also Read: The Reasons for Using RFID in the Warehouse

Future Trends in RFID Technology for Warehouse Automation

RFID technology is constantly growing. It could become even more advanced, with features like:

- Improved Range and Accuracy: New developments in RFID technology could increase the range of RFID readers. It will allowing for more efficient tracking of goods in large warehouses.

- Integration with AI: Combining RFID with AI could lead to smarter systems. It automatically adjust to changing inventory levels and improve stock predictions.

- Mobile RFID: RFID-enabled mobile devices could make it easier for warehouse workers to scan products on the go, reducing downtime and improving productivity.

Also Read: How RFID Is Taking Warehousing to the Next Level?

Final Words

RFID solutions for warehouse automation are changing how businesses manage their inventory. From speeding up operations to reducing human errors. If you run a warehouse, using RFID technology can make things easier. It helps you work faster, save money, and see your stock in real-time. As the technology grows, it can do even more to improve warehouse management.

Connect with Aeologic Technologies for expert RFID solutions to boost your warehouse efficiency!