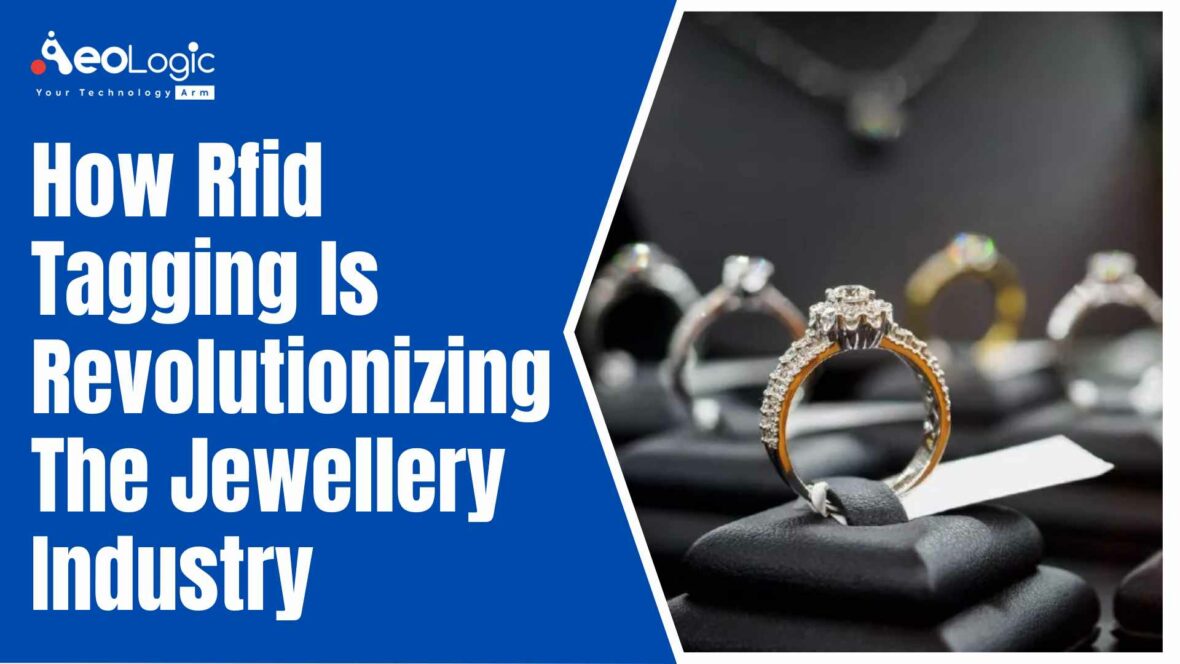

Jewelers across the countries are dealing with very expensive and often very small products. Ranging from tiny diamonds to wristwatches, to rings, pendants, earrings, cufflinks, etc. Moreover, the materials are varied and costly, such as gold or platinum and valuable gems. The cost of brand and used design is also credited to their value. This is why, in this business sector, different security systems and insurance companies are involved. These are requiring a very detailed justification of inventories and security with thorough reports. RFID tagging in the jewelry industry has been quite a help in that sector so far. Even also, helps in tracking inventory with an RFID tagging feature.

In connection with what I have mentioned above, RFID tagging is a major element for the optimal functioning of all the procedures included in the concerned departments.

Also read: How to Implement RFID in the Automotive Supply Chain

When it comes to jewelry, counting these pieces by hand with the help of barcodes is an intensive and time-consuming task. Subsequently, the implementation of RFID tagging in the jewelry industry has implied an improvement and savings. Furthermore, incorporating RFID features is bringing a massive benefit to the jewelry industry that was previously lost during losses, work hours, and thefts.

RFID tagging in the jewelry industry

In addition, RFID tagging in the jewelry industry offers an end-to-end solution from the first inventory to the final sale of the product. Each item is marked with an RFID tag by using the option available with which the inventory is fed with information. Thanks to the readers who are located at different strategic points of the store. If items are not tagged within the inventory, RFID generates the alarms. Isn’t that what you would require in your jewelry tagging system?

Boost your business with our RFID Solutions!

RFID tagging turns the difficult task of items traceability which needs a lot of security easier, with this system accounting and control are carried out more rapidly and accurately. RFID technology in jewelry software is helping in boosting efficiency and improve working conditions.

Also Read: Benefit Analysis of RFID Library Solutions

Let’s consider the following advantages of RFID tagging in the jewelry industry

1. Rapid and more precise inventory management

2. Constant updating of information in real-time of each item in the inventory

3. Increased security for valuable items

4. Careful individual monitoring of each item

5. Increase in the number of staff efficiency

6. Helping in billing

7. Improved traceability of multiple articles

8. Quick invoicing at the counters and reduced waiting lines

9. Detailed and complete reports by article

In a high-value sector like this one, even a small issue or loss each quarter can be radically expensive, resulting in thousands of dollars in shrinkage that will be affecting the bottom line.

Executing manual stock counting also wastes a ton of time, minimizing efficiency and productivity. This is where RFID tagging can facilitate you in revolutionizing the jewelry business through a rapid and precise tracking inventory. Therefore, by applying RFID tagging, jewelry businesses are leveraging drastic reductions in labor costs and contraction that can generate outcomes in a fast recuperation of the cost of the initial system deployment.

Also read: How Modern Technology is Improving Food Supply Chain

Conclusion

In the diamond and jewelry industry, it is important to maintain a precise and reliable stock. Few companies have strategized and developed jewelry inventory software, including readers, tags, and software designed for monitoring gems and jewelry that are automating the inventory process.

Nevertheless, outdated practices, which come with manual error, can never offer exact and reliable figures. Manual stock counting practice wastes a lot of time, which eventually drives an inefficient and unproductive labor force. This is where RFID tagging in the jewelry industry can revolutionize businesses by accurately and quickly tracking inventories.

Talk to us for a free consultation with our industry experts- support@aeologic.com

FAQs

Can you incorporate RFID to locate goods?

Active RFID is utilizing battery-powered tags that help in advertising their identity to various access points or readers. These access points are then transferring the location of each tagged item to a gateway. Active RFID technology can be used for different types of asset location management and real-time location systems (RTLS systems).

Why is RFID significant in the supply chain?

RFID information about products enables visibility in supply chain management by allocation of information between supply chain partners. Enterprises must persistently improve the quality of their supply chains with the aim to allow visibility of supply chains. And thus, reducing operational costs of supply chains.