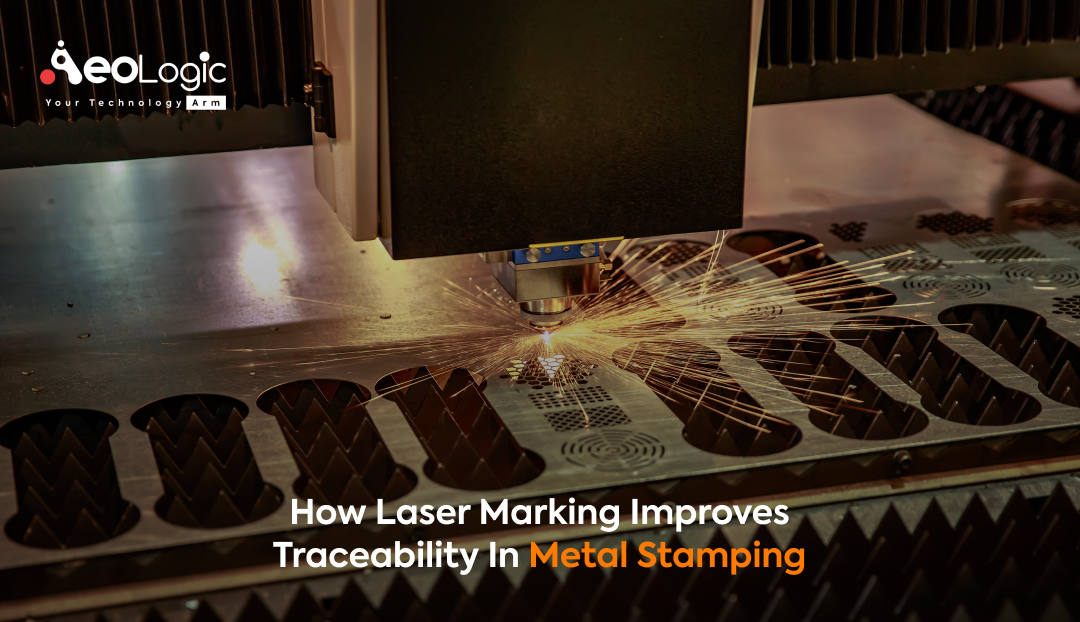

In the world of manufacturing, precision is king, and nowhere is this more evident than in the field of metal stamping. This process shapes metal into high-precision components used in everything from automobiles to electronics. However, with such precision comes the need for meticulous tracking – a concept known as traceability in metal stamping. This article explores how laser marking has revolutionized this vital aspect, ensuring components are not just well-crafted but also well-tracked.

What is Traceability in Metal Stamping?

Traceability in metal stamping refers to the ability to track the history, application, or location of a part throughout its life cycle. It’s vital for quality control, ensuring that if an issue arises, its source can be quickly identified. In sectors like automotive or aerospace, where safety is paramount, traceability isn’t just a luxury; it’s a necessity.

Also Read: Sustainable Traceability in the Food Supply Chain

Challenges in Achieving Traceability

Maintaining traceability in metal stamping isn’t without its challenges. Traditional marking methods can fade or become illegible, and the vast number of parts produced makes tracking each component a daunting task.

Maintaining traceability in metal stamping presents several challenges:

- Durability of Markings: Traditional marking methods can wear off or degrade over time, especially under harsh conditions like high temperatures or exposure to chemicals.

- Volume of Production: The high volume of parts produced in metal stamping makes it challenging to track each component accurately.

- Complexity of Parts: Metal stamped parts often have complex shapes and sizes, making it difficult to apply consistent and readable markings.

- Integration with Systems: Ensuring that the marking technology integrates seamlessly with existing inventory and tracking systems can be problematic.

- Cost Constraints: Implementing a robust traceability system can be costly, and smaller manufacturers may struggle with the investment required.

The Impact of Laser Marking on Traceability

Laser marking uses concentrated light to etch markings onto surfaces, a method becoming increasingly popular in metal stamping. These markings can include serial numbers, barcodes, or QR codes, providing a wealth of traceable information. The process involves using a laser beam to alter the surface of a material, which can be finely tuned for different metals and finishes. This versatility makes it ideal for various applications in metal stamping.

Moreover, laser marking can be automated and integrated into existing production lines, enhancing efficiency and ensuring consistent quality in markings, a critical factor in traceability in metal stamping.

Also Read: Advantages of ERP Traceability for the Food Industry

Top Advantages of Laser Marking for Traceability in Metal Stamping

- Durability: Laser markings withstand extreme conditions, including heat, corrosion, and abrasion, ensuring that they remain legible for the lifetime of the metal part. This durability is a cornerstone of reliable traceability in metal stamping.

- Precision: With laser marking, the level of detail is extraordinary. Even on the smallest of components, laser marking can produce clear, precise markings essential for traceability.

- Non-Intrusive Process: As a non-contact technique, laser marking does not compromise the structural integrity of the metal component, maintaining its quality and lifespan.

- Speed and Efficiency: Laser marking is not only precise but also quick, making it ideal for high-volume production lines where maintaining traceability in metal stamping is crucial.

- Versatility: Laser marking technology is adaptable to various metals and complex shapes, making it a versatile solution for different stamping needs. This flexibility is vital for industries that require diverse metal parts, each needing clear traceability.

- Customization and Security: Laser marking can be easily customized for different applications, including unique identifiers for enhanced security. This feature is particularly beneficial for traceability in metal stamping, as it prevents counterfeiting and ensures authenticity of the parts.

Also Read: Traceability Solutions for Food and Beverage Packaging Industry

The Future of Traceability in Metal Stamping

As we embrace a future driven by technological advancements, the realm of traceability in metal stamping is on the cusp of a transformative era. Laser marking, a cornerstone in current methodologies, is set to evolve, integrating with cutting-edge technologies to redefine how we track and manage metal components.

Technological Integration

The integration of laser marking with technologies like IoT solutions or RFID solutions, and AI promises a new era in traceability in metal stamping, offering more efficient real-time tracking and automated quality control. This will enable manufacturers to monitor parts with unprecedented precision, potentially linking each component to a digital twin for real-time data analysis and predictive maintenance.

Environmental and Economic Impact

Laser marking, being more sustainable and reducing the need for consumables, has significant long-term economic benefits. Its energy-efficient process and reduced waste output align with growing environmental sustainability goals in manufacturing, potentially leading to greener production methods and lower carbon footprints.

Advanced Data Management

Future data management systems, integrated with laser marking, could allow manufacturers to track a part’s entire history, from raw material sourcing to end-user delivery. This enhanced traceability will be crucial in complex supply chains, enabling better quality assurance and more efficient recall processes if needed.

Enhanced Compliance and Safety

In industries facing stringent regulations, advanced laser marking will be key in compliance and safety, providing accurate traceability for every component. This will not only aid in regulatory compliance but also enhance consumer trust, as companies can readily prove the integrity and origin of their products.

Global Supply Chain Efficiency

Laser marking could standardize traceability globally, simplifying international trade and supply chain management. This standardization would enable smoother transitions and tracking of parts across borders, reducing logistical complexities and improving overall supply chain transparency.

Personalized Product Tracking

In consumer markets, enhanced traceability could lead to personalized tracking, allowing customers to access detailed histories of the products they buy. This transparency can strengthen brand loyalty and consumer confidence, as buyers become more informed about the origins and quality of their purchases.

Integration with Smart Manufacturing

Integrating laser marking in smart manufacturing could optimize traceability, leading to more efficient and error-free production lines. In a smart factory, laser-marked components could be automatically tracked and sorted, reducing manual errors and enhancing overall production efficiency.

Also read: What do Traceability Solutions Mean to Your Business?

Final Words

Laser marking is revolutionizing traceability in metal stamping, with benefits ranging from durability to security. Looking ahead, the integration of this technology with advanced data systems, compliance measures, and smart manufacturing promises to elevate traceability standards, ensuring that metal components are not only of high quality but also thoroughly traceable, meeting the demands of modern manufacturing and consumer needs.

Laser marking stands as a pivotal innovation in advancing traceability in metal stamping, setting new standards in manufacturing quality and efficiency. For those looking to embrace these cutting-edge advancements, Aeologic Technologies emerges as a trusted partner, offering expertise and solutions tailored to the evolving landscape of industrial traceability.