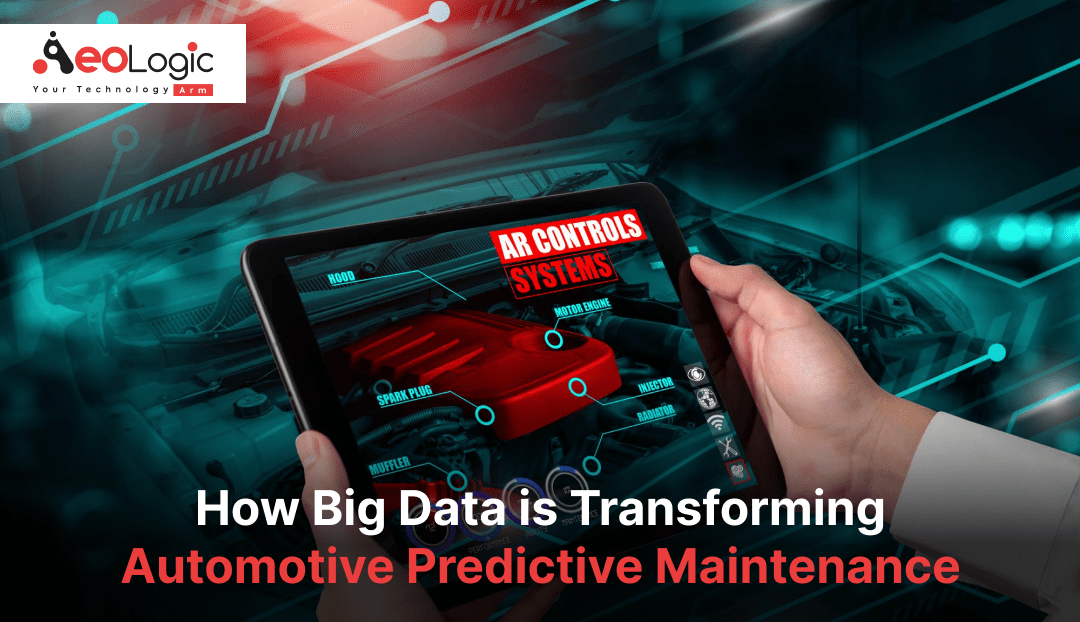

The automotive industry has experienced profound changes over the years, evolving from its mechanical origins to a sophisticated digital landscape. This digital transformation has drastically altered how automotive companies operate, make decisions, and engage with customers. At the heart of this revolution is data analytics, which is playing a pivotal role in enhancing operational efficiency, quality management, and overall business intelligence. Automotive predictive maintenance, powered by Big Data, exemplifies these advancements and offers a range of benefits that are reshaping the industry.

Also read: Impact of Digital Transformation on the Automotive Industry

Types of Data Collected for the Automotive Predictive Maintenance

In the modern automotive world, data collection for automotive predictive maintenance spans a variety of sources, each providing crucial insights:

- In-Vehicle Sensors Data: Vehicles today are outfitted with numerous sensors that monitor parameters such as speed, acceleration, braking, fuel consumption, and engine performance. This data provides real-time insights into how the vehicle operates and driver behavior, helping to identify potential issues before they become serious problems.

- GPS and Navigation Data: GPS systems track the location and movement of vehicles, offering valuable information on real-time traffic conditions and route optimization. This data can enhance the driving experience by suggesting the most efficient routes and helping to avoid traffic congestion.

- Connected Cars Data: Connected vehicles transmit data about real-time performance, maintenance needs, and driver behavior to manufacturers and service providers. This constant flow of information helps in monitoring vehicle health and planning necessary maintenance activities.

- Vehicle Health Metrics: Data on fuel efficiency, tire pressure, and engine performance is critical for maintaining vehicle health. Monitoring these metrics helps in ensuring that the vehicle operates efficiently and reduces the likelihood of breakdowns.

- Environmental Data: Weather conditions and road quality impact vehicle performance and safety. Collecting and analyzing this data helps in understanding how external factors affect driving conditions and vehicle operation.

- Maintenance Records: Historical data on car repairs and servicing is essential for predictive maintenance. By reviewing past maintenance records, companies can forecast future needs and improve vehicle reliability.

- Marketing Data: Data from marketing activities, customer engagement, and sales conversion rates provide insights into customer preferences and market trends. This information is used to tailor marketing strategies and improve customer targeting.

- Personal Information: Detailed personal data, such as purchasing history, web browsing habits, and preferences, is collected to enhance customer experience and customize offerings. However, this data must be handled with care to ensure privacy and security.

Effectively leveraging these diverse data sources is crucial for automotive predictive maintenance companies to unlock new growth opportunities and drive innovation.

Benefits of Big Data Analytics in Predictive Maintenance

Big Data analytics has brought transformative benefits to the automotive industry, particularly in the realm of predictive maintenance. Here’s a closer look at these advantages:

Enhanced Predictive Accuracy:

- Real-Time Monitoring: The continuous collection and analysis of real-time data from vehicle sensors enable manufacturers to keep track of component conditions and predict potential failures with high accuracy. This proactive approach helps in addressing issues before they escalate into major problems.

- Advanced Analytics: Machine learning algorithms and statistical models analyze both historical and real-time data to forecast potential issues. These advanced analytical methods offer more precise predictions compared to traditional maintenance practices, allowing for timely interventions.

Reduced Downtime:

- Proactive Maintenance: Instead of waiting for a component to fail, predictive maintenance schedules repairs or replacements based on data-driven forecasts. This approach significantly reduces unexpected breakdowns and minimizes vehicle downtime.

- Optimized Scheduling: Maintenance activities can be planned during scheduled service intervals or when the vehicle is not in use. This strategic scheduling reduces disruptions to vehicle operation and enhances overall efficiency.

Cost Savings:

- Preventive Repairs: By identifying and addressing potential problems before they become serious, predictive maintenance helps avoid costly emergency repairs and replacements. This proactive approach is more cost-effective in the long run.

- Efficient Resource Use: Maintenance efforts are streamlined, and parts are ordered and replaced as needed, reducing the need for a large inventory of spare parts. This approach helps in managing costs and optimizing resources.

Improved Vehicle Longevity:

- Extended Component Life: Regular and timely maintenance, based on data insights, prevents excessive wear and tear on vehicle components. This extends the lifespan of the vehicle and its parts, ensuring they perform well over time.

- Optimized Performance: Well-maintained vehicles operate more efficiently, resulting in enhanced overall performance and better fuel efficiency. This not only improves the driving experience but also reduces operating costs.

Utilization of Automotive Data

The vast amounts of data generated for the automotive predictive maintenance require advanced technologies for effective processing and analysis. Traditional data processing tools are often insufficient for handling these large datasets, necessitating the use of sophisticated methods and technologies to derive valuable insights.

Key Users of Automotive Data and Their Applications:

- Car Manufacturers: Manufacturers use data analytics to enhance vehicle design, production processes, supply chain management, and quality control. By analyzing data from in-vehicle sensors, manufacturers can monitor critical metrics such as engine performance and fuel efficiency, identify potential issues early, and maintain high safety and performance standards.

- Fleet Managers: Fleet managers rely on data to improve the efficiency and reliability of their vehicle fleets. By analyzing GPS and telematics data, they can optimize routes, reduce fuel consumption, and enhance overall fleet performance. Maintenance data is crucial for scheduling preventive maintenance, reducing vehicle downtime, and extending fleet lifespan.

- Insurance Companies: Insurers use data analytics to assess risk and offer personalized insurance rates. By analyzing driving behavior data, they can identify safe drivers and offer them lower premiums. Additionally, data from connected cars provides detailed insights into accidents, aiding in claims processing and fraud detection.

- Marketing Teams: Automotive marketing teams use data to understand customer preferences and behavior, informing their marketing strategies. By analyzing data from social media, customer demands, and sales trends, they can create targeted marketing campaigns that resonate with specific customer segments, improving engagement and driving sales.

Also read: Industry 4.0 Technologies Transforming Automotive Manufacturing

Conclusion

Automotive companies that effectively harness customer data can benefit from platforms like Aeologic Technologies, which facilitate collaboration with AI model providers and adjacent businesses. Through the power of Big Data, the automotive industry is not only enhancing predictive maintenance but also driving innovation and improving overall operational efficiency.