The manufacturing industry produces a wide range of products and distributes them globally to meet the needs of people. Currently, it is a fast-growing industry and important for daily life span. Here are a few stats related to the manufacturing industry that can make you more clear about the existence of this industry.

-

- Value added in the Manufacturing market is projected to be US$8.8tn in 2024.

-

- A compound annual growth rate of 1.15% is expected (CAGR 2024–2029).

-

- The value added per capita in the Manufacturing market is projected to amount to US$1,135.0 in 2024.

-

- The value-added margin in the Manufacturing market is projected to amount to 25% in 2024.

-

- Output in the Manufacturing market is projected to amount to US$35.1tn in 2024.

-

- A compound annual growth rate of 1.10% is expected (CAGR 2024–2029).

It is important to make quality products as this helps organizations to regain customers and to build a better customer interactive environment. However, many stages or processes have various issues or challenges, resulting in a drop in quality in the manufacturing industry. There are issues like not detecting defects, unavailability of predictive maintenance with manual monitoring, data overload, training, and skill gaps, and also not providing better customer experience. These mentioned problems cannot be cured with manual handling alone, this is where software solutions for manufacturing businesses come in, offering the proper tools and technology to ensure efficiency and quality.

Overview: How AI is Enhancing Quality Control and Boosting Efficiency

Artificial intelligence is a powerful technology that drives solutions to improve the quality and efficiency of the manufacturing industry. It has the potential to make solutions that can have a positive effect on every aspect. Many developed regions have already implemented this technology-powered solution. AI technologies are transforming manufacturing quality control by using machine vision-based automated inspections for accurate detection, predictive analytics to anticipate problems, and real-time monitoring to enable prompt remedial action.

By evaluating supplier performance, they improve supply chain management, aid in defect root cause analysis, and optimize manufacturing processes. Few top companies provided stats about the existence of AI solutions in the manufacturing industry as the global market size for AI in manufacturing was $5 billion in 2023 and is forecast to reach $68 billion by 2032 (Precedence Research). AI is projected to increase productivity by 40% or more in the manufacturing industry by 2035 (Accenture).

In this article, we will see the role of AI solutions to enhance quality control in the manufacturing industry. We will also see the additional details like benefits, challenges, etc and at last, we will end the discussion with a few final words.

Related blog: The Power of Manufacturing Automation Solutions

What are AI Solutions for Enhancing Quality Control in Manufacturing?

Artificial intelligence solutions are advanced technologies that use algorithms, data analysis, and computational power to automate processes, make predictions, and learn from data without explicit programming.

There could be many solutions with AI that can enhance quality in the manufacturing industry, such as machine vision systems for defect inspection, predictive analytics to anticipate quality problems, and automated inspection tools that guarantee consistency are some examples of AI methods for improving quality control in manufacturing. Overall, AI-powered solutions not only improve quality but also help the manufacturing industry to grow to enhance the world’s GDP.

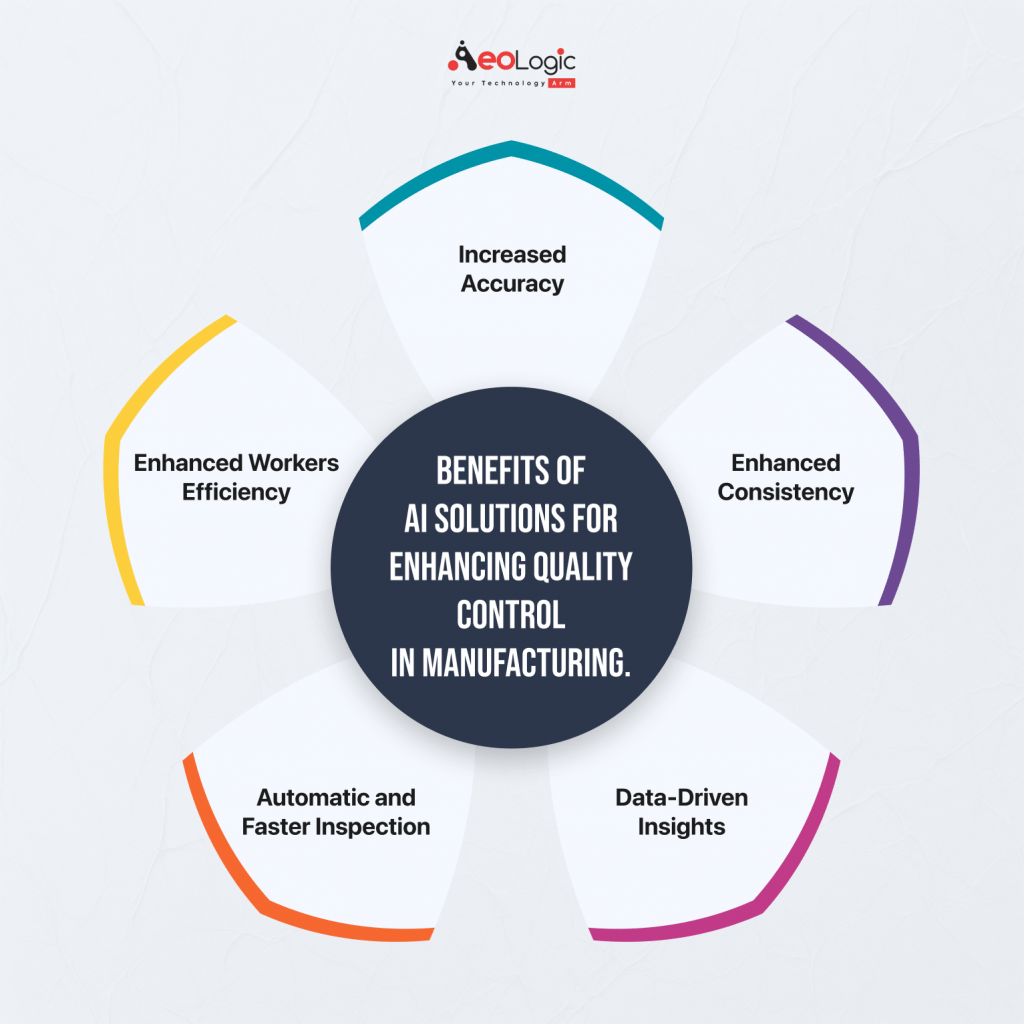

Benefits of AI Solutions for Enhancing Quality Control in Manufacturing

There are a lot of benefits of AI solutions for enhancing quality control in the manufacturing industry as here are a few key benefits mentioned below.

Increased Accuracy

It is important to have a lower defect rate in the manufacturing of products but with the manual monitoring of defects cannot maintain the accuracy at the highest level. This does not help to enhance the quality of the manufacturing industry. Where AI-powered solutions-based technologies reduce human error and guarantee high-quality products by precisely detecting and analyzing defects.

Enhanced Consistency

Consistency is the key to success in any task, so it is important in the manufacturing industry too. It is important to be consistent in maintaining product quality over time. This helps to balance the quality and also not waste too much time. However, this is not wholly possible with the traditional maintenance tool as AI solutions can enable more consistent product quality results from uniform implementation of quality criteria.

Data-Driven Insights

Data or information plays a crucial role in decision-making and also in analyzing past decisions. Manual gathering and analysis of data can take too much time and it is not guaranteed that the extracted information could be fully accurate. Where AI-powered solutions provide extensive data analysis and offer practical insights that enhance decision-making and process optimization.

Enhanced Workers Efficiency

Workers’ efficiency also matters too much as this can only be enhanced by real-time feedback on which portion needs to improve. The manual method of getting feedback takes too much time and cannot help to increase workers’ efficiency. As with the AI solutions employees can concentrate on higher-value tasks to reduce manual inspection burdens and provide real-time feedback.

Automatic and Faster Inspection

Inception is important as only not inception but at a faster rate without affecting quality is more important. Where with AI-powered solutions, manufacturers may sustain high production rates without compromising quality thanks to automated inspections, which expedite the quality control process.

Related blog: Inventory Management With RFID Tags In Manufacturing

Challenges in Implementing AI Solutions in Manufacturing Industry

We have seen a lot of benefits but there are a few challenges too. Here are a few challenges that are mentioned below.

-

- Integration with existing systems can be a challenge; operations may be disrupted as a result of the complexity and potential need for major changes when integrating AI into older systems.

-

- Initial implementation cost can be a challenge as AI solutions infrastructure can be unaffordable for many companies.

-

- AI model development and optimization can be challenging, needing certain expertise and resources that might not always be available.

Related blog: The Benefits of Using Automation in Manufacturing

Final Thoughts

By increasing the precision, effectiveness, and consistency of quality control procedures, artificial intelligence-powered solutions have great potential to improve industrial quality. They make proactive problem-solving possible, lower defect-related expenses, and offer data-driven insights that support well-informed decision-making. This also cannot neglect that there are some challenges too but that should be overcome with advancement.

Many big manufacturing industries have taken help from Aeologic Technologies and got a positive result. Manufacturers may improve operations, adjust to market demands, and eventually produce higher-quality goods that increase consumer satisfaction by utilizing AI technologies. Implementing AI solutions will be essential for maintaining competitiveness and promoting innovation in quality management as the sector develops.