This is the world of efficiency and innovation. In our recent blog post, we introduced the concept of factory automation solutions for change. Read about high technology, in which applications and science mesh to raise production efficiency, cut costs, and enhance quality. We encourage you to come and find out for yourself how automation can help your business go forward.

What is Factory Automation?

Factory automation means the use of computer and robot technology on production lines. This reduces the work of man’s hands, resulting in greater efficiency, consistency and safety. Key aspects include:

Technology Integration: Process control through robotics, artificial intelligence and software.

Process Optimization: The systems use computer-aided quality controls and operate with total efficiency.

Use of Robotics: There are such jobs as assembly, handling and welding work which the robot can do better or more quickly than a human being.

Data Analysis: Production system management systems collect production information and undertake an analysis of that information in order to help improve its management.

Enhanced Safety: Moreover, automation removes human error and danger from the workplace.

Scalability and Flexibility: Easier to expand, and can be adapted for different manufacturing needs.

Energy Efficiency: Automated systems can lower energy consumption and limit environmental impact.

Automation of the factory is an important element in modern manufacture, increasing productivity and competitiveness.

Also Read: How Automation is Transforming Manufacturing in India

Automation Types: How Does It Work?

- Programmable: The software and machines are adjusted to meet the needs of product customisation. This type of automation is employed when producing products in batches with varying features.

- Flexible: This is tailored to the sort of goods. It is faster to execute than the prior one.

- Fixed: For specified programming procedures in which the product design cannot be changed.

- Integrated systems: Integrated systems are independent machinery and processes that operate in the same plant.

An automated factory can operate in a variety of ways. Machines, for example, are automated, yet they are overseen by a human who conducts some tasks. There may also be certain automated machines in operations that do not involve people, such as those designed for a repetitive task or the complete production line. Simultaneously, not all tasks necessitate the same level of automation. In tasks such as manual product assembly or product modification, for example, the use of technology might be modest and subjugated to the reasonable evaluation of people.

Boost your business performance with our automation solutions!

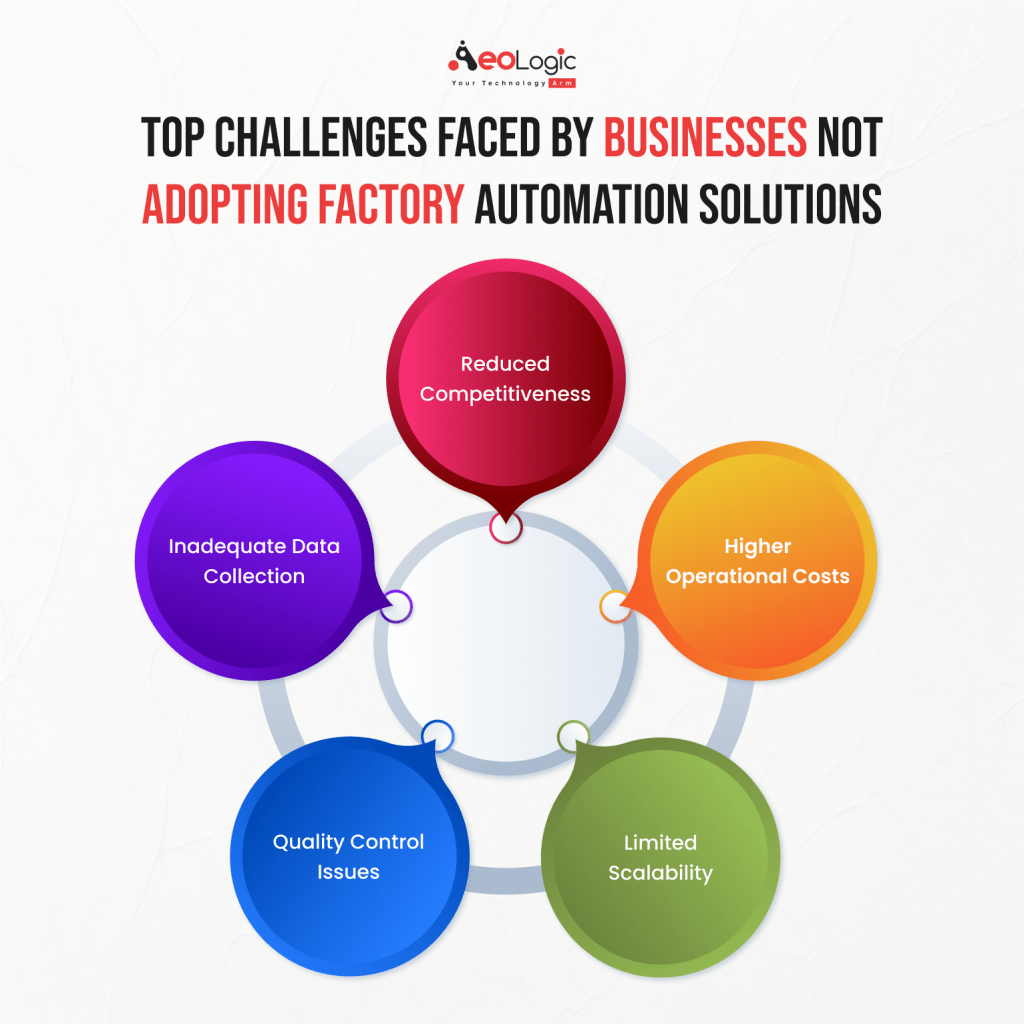

Top Challenges Faced by Businesses Not Adopting Factory Automation Solutions

Reduced Competitiveness: Yet in an age when everyone else is using automation to boost productivity, those who resist may be pulled behind the pack. Automation can improve production speed, uniformity, and accuracy. Without that, businesses might not be able to compete in price, quality, or production.

Higher Operational Costs: However automated procedures are almost always less labor intensive and more efficient than manual ones. That means higher labor costs and longer production periods. Also, the possibilities for human error in manual operations not only waste time but also result in higher material costs. On the contrary, automation can make use of resources efficiently minimize waste, and lower operational costs.

Limited Scalability: Increasing production volume in a traditional non-conveyorized facility is often difficult and expensive. Such an operation usually involves large-scale manpower, and even then, it may not approach the efficiency of an automated system. The advantage of automation is that it can be scaled up much more smoothly. One can usually expand production without incurring much extra cost once the investment is made in machinery.

Quality Control Issues: Without automatic controls it is difficult to maintain constant quality. The precision and uniformity of automated systems is therefore higher, and the scope for error lessened. In manual processes, variations in human performance will result in variations in the end product, thus damaging brand recognition and customer satisfaction.

Inadequate Data Collection and Analysis: More frequently, modern automated systems are equipped with data analysis systems. This data is essential for refining production processes, anticipating maintenance requirements, and understanding business operations. With automation, your firm would have access to these insights, enabling you to quickly adapt to changes in the market and become more efficient.

All in all, it is a good bet that businesses that put off introducing factory automation for too long will be prisoners to inefficiency, unable to compete in terms of price, control costs, expand production, ensure uniform quality, or make informed choices based on data.

Also Read: Top Ways Robotics Are Making Life Safer

Top Benefits of Factory Automation Solutions

Alright, buckle up and get ready for the ride of your life! We’re about to dive into the mind-blowing world of factory automation and all the incredible perks it brings to the table. Get ready to have your socks knocked off!

- The magical ability to get more done in the same amount of time, makes your coworkers wonder if you’ve secretly hired a team of highly efficient clones.

Best Factory automation solutions are like the superheroes of the manufacturing world, swooping in to save the day by making production processes as smooth as butter. They’re like the cool kids who effortlessly reduce manual labour and human error, leaving us mere mortals in awe of their efficiency. It’s like having a team of robots who never complain, never take coffee breaks, and never mess up. Who needs humans when you have automation? This leads to higher productivity as tasks are executed with the grace and finesse of a synchronised swimming routine, resulting in increased output and faster turnaround times that would make even The Flash jealous.

- Enhanced Awesomeness and Unicorn-like Consistency

Automation systems are like the superheroes of the manufacturing world, swooping in with their high accuracy and precision to save the day from pesky variations in product quality. They’re like the Batman of the assembly line, ensuring that every product is top-notch and leaving no room for error. Move over, human workers, the automation systems are here to show us how it’s done.

Automation swoops in like a superhero, saving the day by getting rid of those pesky human errors and inconsistencies. It’s like having a personal assistant who never messes up and always follows the rules. With automation, products are guaranteed to meet consistent standards, making customers jump for joy and reducing waste or rework. It’s like magic, but without the rabbits or top hats.

- Super-Duper Safety Deluxe Edition

So, picture this: factory automation solutions are like having a bunch of little robot superheroes running around, saving the day. They fearlessly take on all the hazardous tasks and work in those “oh-so-dangerous” environments. It’s like having a team of Iron Man and Wonder Woman making sure everything gets done without anyone getting hurt.

By swapping out clumsy humans with sleek automation, workplace safety gets a major upgrade. Say goodbye to accidents and injuries, and hello to a future where robots rule the risky roost.

- How to Make Your Wallet Cry Less

While the initial investment in automation technology can be as painful as stepping on a LEGO, it’s like finding a pot of gold at the end of a rainbow – long-term cost savings that’ll make Scrooge McDuck jealous. Automation is like the ultimate coupon code for businesses – it slashes labour costs by replacing humans with machines.

Say goodbye to an extensive human workforce and hello to a team of hardworking robots. It’s like having your army of efficient, tireless workers, without the need for coffee breaks or vacation days. Who needs humans anyway when you can have machines doing all the heavy lifting? Not only does it magically make errors, waste, and rework disappear, but it also transforms your business into a money-making machine. Say hello to efficiency and profitability like you’ve never seen before.

5. The magical ability to make your business grow like a beanstalk on steroids. It’s like having a superpower.

Factory automated systems are like the superheroes of production. They can effortlessly handle more products than a buffet table at an all-you-can-eat restaurant, juggle more variations than a circus performer with a dozen balls, and adapt faster than a chameleon at a fashion show. These machines are the real MVPs of the manufacturing world. The magical powers of scalability and flexibility.

With these superpowers, businesses can swoop in and save the day, responding swiftly to market demands like caped crusaders. They can outmanoeuvre their competitors in this wild and unpredictable business jungle, like nimble acrobats performing daring feats. It’s like watching a thrilling circus act, but with spreadsheets and profit margins instead of trapeze artists and lions. So, buckle up and get ready for the exhilarating ride of staying competitive in this dynamic environment.

Checkout Our Trending Blog: How Are Automation and Robotics Will Impact Your Employment

Why Choose Aeologic for the Best Automation Solution?

There are advantages in choosing Aeologic for automation. Proud of its pioneering spirit, Aeologic offers leading-edge industry-use automation systems. To help host organizations cut down on operations and work more effectively, they design their solutions with dependability, scalability and efficiency in mind. culturally significant But what truly sets Aeologic apart from the market is that it returns to a high-tech way of using tools, employing artificial intelligence and robotics for automation in an attempt to both raise output while maintaining quality.

Thus another popular company with organizations looking for simplification and upgrading has been Aeologic, who are most noted for their devotion to improving customer service. Therefore, they not only produce the product but become a long-term companion on the path of automation.