Global manufacturers are utilizing IoT in predictive maintenance to transform traditional manufacturing plants into smart factories, as digital transformation becomes a top priority in the Industry 4.0 era. This approach leverages AI and machine learning. It allows the manufacturer or producer to anticipate the probable shutdown of critical revenue-generating apparatus.

This enables them to make precise predictions and schedule the most optimal time for maintenance, thereby significantly reducing or avoiding unplanned delays and reducing operational overheads. As the best IoT solutions provider, we ensure that our technologies are tailored to meet these critical needs efficiently.

First, let’s understand what actually is IoT predictive maintenance.

What Is IoT Predictive Maintenance?

Internet of Things (IoT) Predictive maintenance systems use data-collecting sensors to learn about the state of machinery and equipment while they’re running, and software analytics to report on possible issues or failure risks.

In order to allocate resources effectively, manufacturers can use this trustworthy data to better predict when servicing needs will arise and which components may need replacement. This, in turn, can help manufacturers save money on costly repairs and make better predictions about future needs.

Now let’s look at a list of the top benefits of IoT Predictive Maintenance in manufacturing industry.

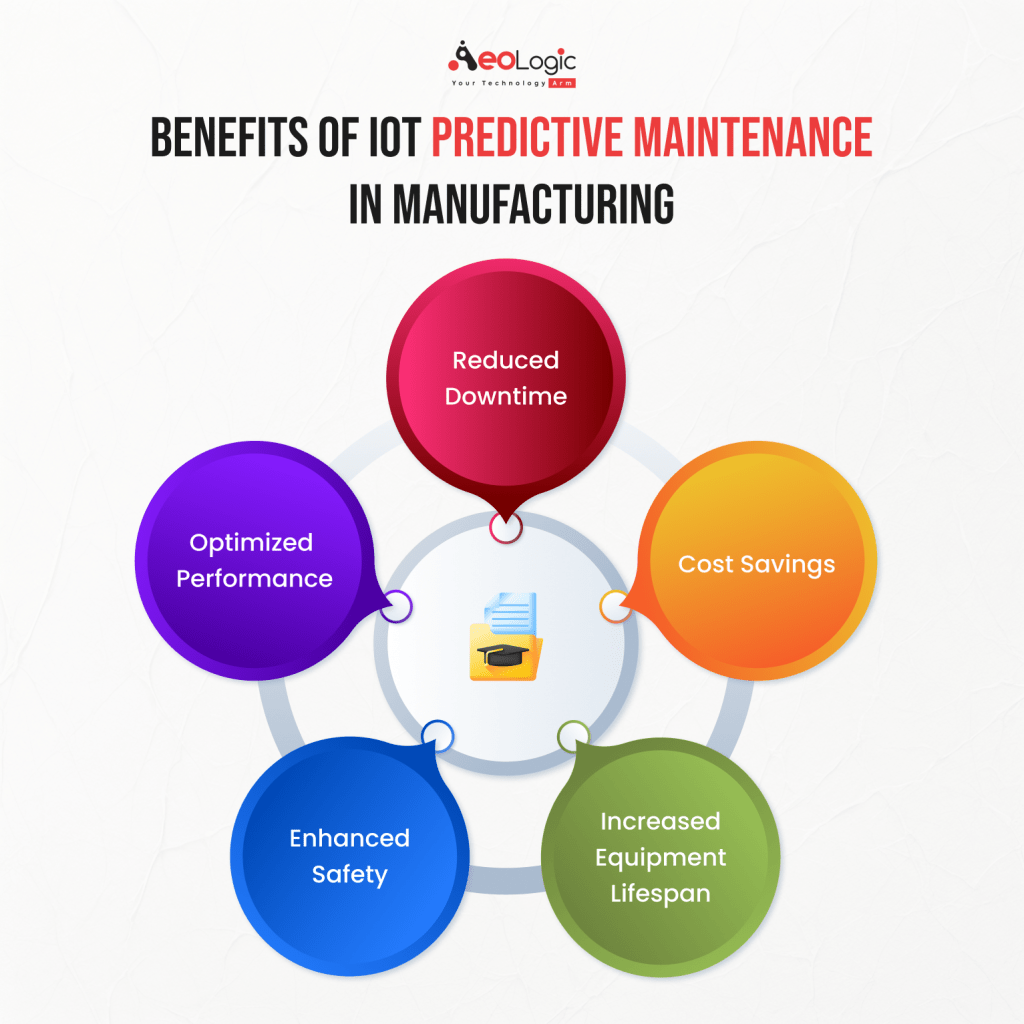

Benefits of IoT Predictive Maintenance in Manufacturing

1) Cut Maintenance Expenses

Each resource has several related expenses; yet, unexpected failure cost greatly influences the overall cost of ownership of any asset. Companies can thus save money by being able to forecast and prevent equipment breakdown. In sectors with lots of assets, better maintenance planning can save quite a lot. IoT-based predictive maintenance uses historical data from many sources—including IoT devices and sensors—to create accurate forecasts about asset health, use, and failure probability, so guiding your actions. IoT-based predictive maintenance lets you methodically arrange the best maintenance and inspection schedule to save unneeded effort and unforeseen downtime. One can drastically cut avoidable expenses as well as the duration of time the machinery or equipment is down for maintenance.

2) Improve Efficiency in Using Assets

Profitability is negatively impacted when there is unplanned downtime as a result of equipment failure, expenditures incurred as a result of production delays, and substantial costs associated with maintenance and repairs. By allowing for the prediction of machine breakdowns and the reduction of maintenance concerns, Internet of Things-based predictive maintenance makes it possible to make more efficient use of assets that are already in existence. It can assist in determining the factors that lead to delays, whether those factors are internal or external, and it can lend a hand in establishing procedures to deal with these factors. It is also possible for Internet of Things-based predictive maintenance to identify potential problems with equipment before they become operational and to provide early warnings, thereby enhancing asset availability, reliability, and performance.

3) Extend the Asset Life

You are able to monitor, manage, and optimize assets through the use of Internet of Things-based predictive maintenance, which results in improved availability, utilization, and performance. Through the use of real-time monitoring, you may improve your visibility into assets, which will eventually enable you to anticipate the breakdown of machines and locate components that require replacement. You have the ability to schedule maintenance and repairs, anticipate occurrences before they take place, and receive notifications in real time that enable you to take prompt action, which ultimately results in an extension of the life of your assets.

4) Increase Field Crew Efficiency

Asset monitoring systems that are based on the Internet of Things make it possible for businesses to monitor the condition of field assets at frequent intervals. Having a comprehensive perspective of the state of assets can be beneficial to businesses in terms of task planning, priority, and scheduling. As a result of unanticipated downtime or equipment failure, it is frequently necessary to reallocate field service crews from other work locations in order to solve the issue. Additionally, employing additional personnel or completely rescheduling other planned maintenance tasks may also be necessary. It is possible to avoid this by utilizing Internet of Things-based predictive maintenance, which will result in an increase in the utilization and reaction times of field service team, as well as a reduction in the duration of maintenance and asset downtime.

5) Increase Safety and Compliance

Using the Internet of Things (IoT), predictive asset maintenance gives businesses the ability to foresee and solve potential safety risks, as well as to anticipate prospective issues before they have an effect on personnel. Due to the fact that they analyze data from a variety of sources, including both internal and external sources, as well as the data generated from Internet of Things devices and sensors, they are able to swiftly take the right actions to eliminate safety hazards. Identifying potentially dangerous circumstances and estimating the influence that they have on working conditions can be accomplished through the analysis of data collected over extended periods of time. You could then trigger orders to reallocate resources and maintain exposure levels below the threshold values, which would be in accordance with regulations, if you integrated with human capital management (HCM) systems.

Final Words

The IoT is changing manufacturing. One of the biggest benefits of IoT technology is predictive maintenance, which helps businesses maximize their resources by preventing equipment problems.

Not every equipment requires predictive maintenance. We have to determine which equipment would benefit the most from minimal downtime. To adopt IoT-based predictive maintenance we need to rank our assets according to previous downtime occurrences. Also, we have to take consequent business loss into consideration.