In the fast-moving consumer goods (FMCG) industry, attention to efficiency and accuracy counts. It is here that GS1 Standards make their appearance, offering a variety of advantages to speed operations and promote development. GS1 Standards provide a common language for identification, capture and sharing of information on products as they move through the global supply chain. Faced with the complexities of production, distribution and compliance as manufacturers of fast-moving consumer goods (FMCG), these standards are key to promoting performance and competitiveness. This article analyzes the 10 greatest benefits of GS1 for FMCG manufacturers, demonstrating that these standards are not just good but necessary in today’s market.

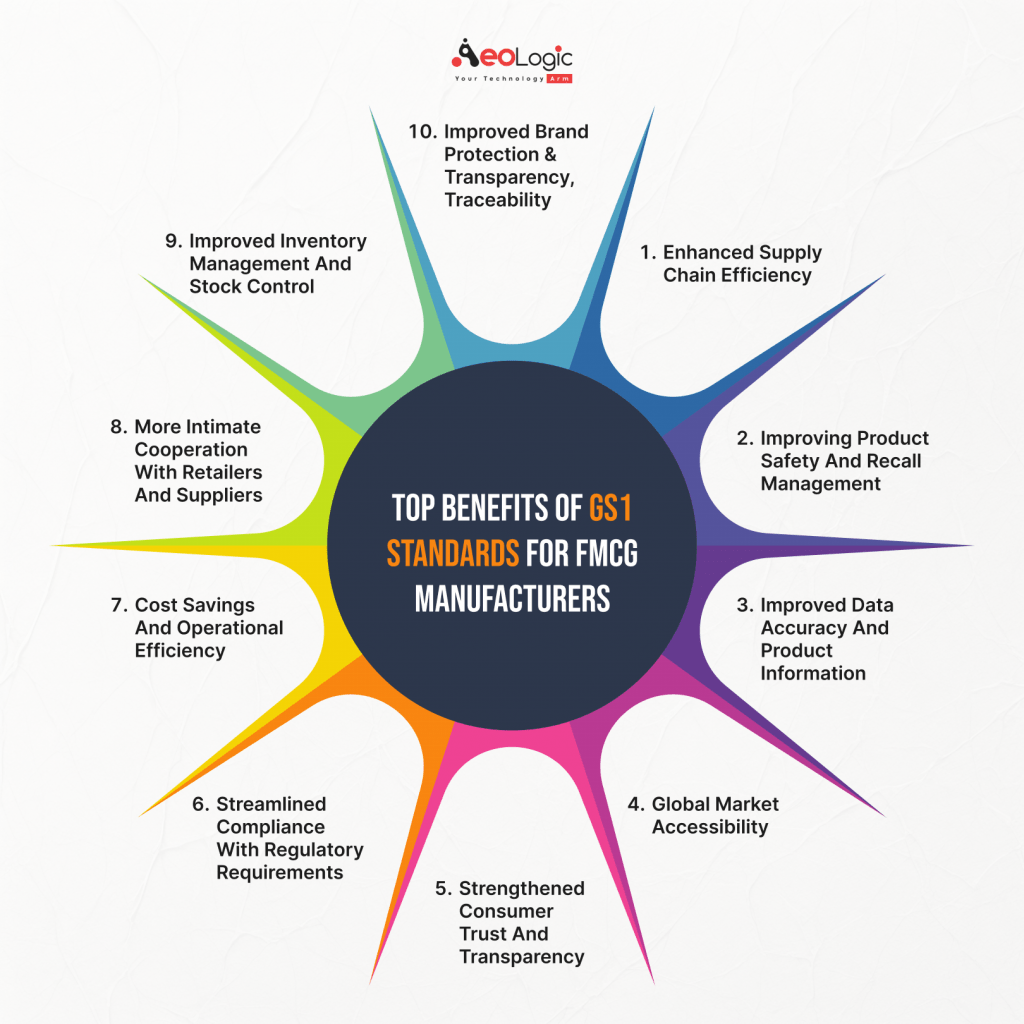

Top Benefits of GS1 Standards for FMCG Manufacturers

Discover the Top Benefits of GS1 Standards for FMCG Manufacturers, a guide to unlocking efficiency and innovation in the fast-paced consumer goods market. Learn how these global standards revolutionize operations, ensuring success and sustainability.

1. Enhanced Supply Chain Efficiency

Greater Supply Chain Efficiency: One of the biggest Benefits of GS1 for FMCG Manufacturers. With GS1 standards, products can be tracked and traced all the way through the supply chain. This means that manufacturers can track their products from the factory floor to store shelves, which in turn leads to better inventory control and less out-of-stock situations. A study commissioned by GS1 US has revealed that using these standards can increase the accuracy of inventory by as much as 63 % (GS1 US).

Also Read: The Role of RPA in the Manufacturing Industry

2. Improving Product Safety and Recall Management

Product safety and recall management are both greatly reliant on GS1 standards. These standards allow FMCG manufacturers to quickly identify, locate, and recall products should there be a safety concern. This rapid response capability not only protects consumers, but also helps preserve brand image. According to the GS1 report, these standards can cut product recall times by up to 75 % (GS1 Global).

3. Improved Data Accuracy and Product Information

GS1 standards guarantee greater data accuracy and more complete product information. GS1 standards are encoded in barcodes and RFID tags, creating precisely specified information from manufacturing details through expiration dates. For FMCG manufacturers, this accuracy is key to managing inventory and providing consumers with reliable product information. According to statistics, the adoption of GS1 standards can increase data accuracy by more than 50% (GS1 U.K.).

4. Global Market Accessibility

GS1 standards are recognized all around the world, which is invaluable to FMCG makers hoping to increase their international share. Thus equipped with these international standards, products can more easily be integrated into various markets from around the world so as to avoid possible obstacles presented by local compliance and labeling requirements. More than 2 million companies around the world use GS1 standards in international trade, they estimate. (GS1).

Also Read – Digital Adoption Advantages for Manufacturers

5. Strengthened Consumer Trust and Transparency

One of them is strengthened consumer trust and transparency. The use of GS1 standards offering detailed information on products makes it possible for consumers to make better purchasing decisions. The transparency that this engenders is what creates the trust and loyalty needed to win in FMCG. According to a survey, 73 % of consumers expect more transparency in FMCG products (Label Insight).

6. Streamlined Compliance with Regulatory Requirements

GS1 standards harmonize compliance with regulatory requirements. Standards that conform to the following regulations make it easier for FMCG manufacturers to follow laws related to product labeling and traceability: Such an alignment lessens the risk of non-compliance and attendant penalties. According to research, compliance with GS1 can reduce regulatory risks by up to 30 % (GS1 Compliance).

7. Cost Savings and Operational Efficiency

For FMCG manufacturers, GS1 standards bring about considerable cost savings and efficiency of operation. Standardizing processes and eliminating manual interventions lowers operating costs for manufacturers. This also means less waste and better resource utilization through more effective tracking and inventory management. A study reveals that GS1 standards reduce costs by 5-10 % (GS1 Efficiency).

8. More Intimate Cooperation with Retailers and Suppliers

Another advantage of GS1 standards is increased cooperation between retailers and suppliers. These standards provide a common tongue for all stakeholders, enhancing communication and cooperation. This partnership is crucial for effective supply chain management and meeting consumer spends on time. According to reports, companies using GS1 standards have seen improvements in collaboration of up to 55 % (GS1 Collaboration).

9. Improved Inventory Management and Stock Control

FMCG manufacturers can greatly improve inventory management and stock control with GS1 standards. Real-time tracking with accurate data means manufacturers can adjust stock levels, avoiding overstocking or shortages. Such efficient inventory management results in increased customer satisfaction and lower storage costs. According to a study (GS1 Inventory Management), GS1 standards can increase the accuracy of inventory by 60 %.

Boost your business performance with our automation solutions!

10. Improved Brand Protection, Anticounterfeiting

Finally, GS1 standards protect the brand and prevent counterfeiting. These standards identify all the products with a unique number, making it impossible for counterfeit goods to slip into the supply chain–a signal benefit for both brand and consumer. GS1 standards provide a traceability that discourages counterfeiting activities. According to reports, GS1 standards can reduce the incidents of counterfeiting by up to 40 % (GS1 Anti-Counterfeiting).

11. Transparency and Traceability

In the supply chain, traceability and transparency are essential. Organisations can have transparency along the whole supply chain and insight into each site where their products halt thanks to GS1 standards. Maintaining product safety requires this tracking.

Consider recalls of products, for instance. If your company has to recall a product, you may quickly obtain the information required to find the product’s location at any given point in the supply chain thanks to transparency and traceability throughout the whole process. Using these guidelines will save a lot of time, which is essential for safeguarding customers and removing tainted products from sale.

However, you might not have full supply chain transparency without GS1 standards if tracking and data-gathering procedures weren’t adequately established. This may cause delays in the recall of affected products, endangering consumers needlessly.

Final Thoughts

The benefits of GS1 for FMCG manufacturers are numerous and crucial to business success. These standards provide a complete solution to modern manufacturing problems, improving supply chain efficiency and countering counterfeit threats. With its implementation of the GS1 standards, FMCG manufacturers can improve not only their own efficiency but also consumer trust and expand their market across borders.