Tracking of each stage of the production process is important in the fast-growing aluminum industry today. Laser traceability is one of the most powerful tools that has transformed this tracking. Laser traceability in aluminum industry is the use of laser technology as a marking and/or tracing of aluminum products from inception to end life stage. The latter presents a broad spectrum of merits that increase the efficiency of some operations conducted throughout the development of aluminum products. This post explains the benefits of laser traceability in the aluminum industry.

Why Laser Traceability is Important in the Aluminum Industry

There are several reasons why laser traceability has become an integral part of the aluminum system. It’s not a technological improvement; it is indeed a strategy. The increasing complexity associated with modern manufacturing processes has generated the need for accurate tracking, quality management as well as regulatory compliance. Because then offers both manufacturers and their customers confidence, laser traceability is a complete solution that improves product quality while lowering costs.

Adoption of laser traceability is a wise move because it entails sustainable developments survival, competitive positions achievement and further progress in an industry certain to keep changing.

Also Read: How Laser Marking Improves Traceability in Metal Stamping

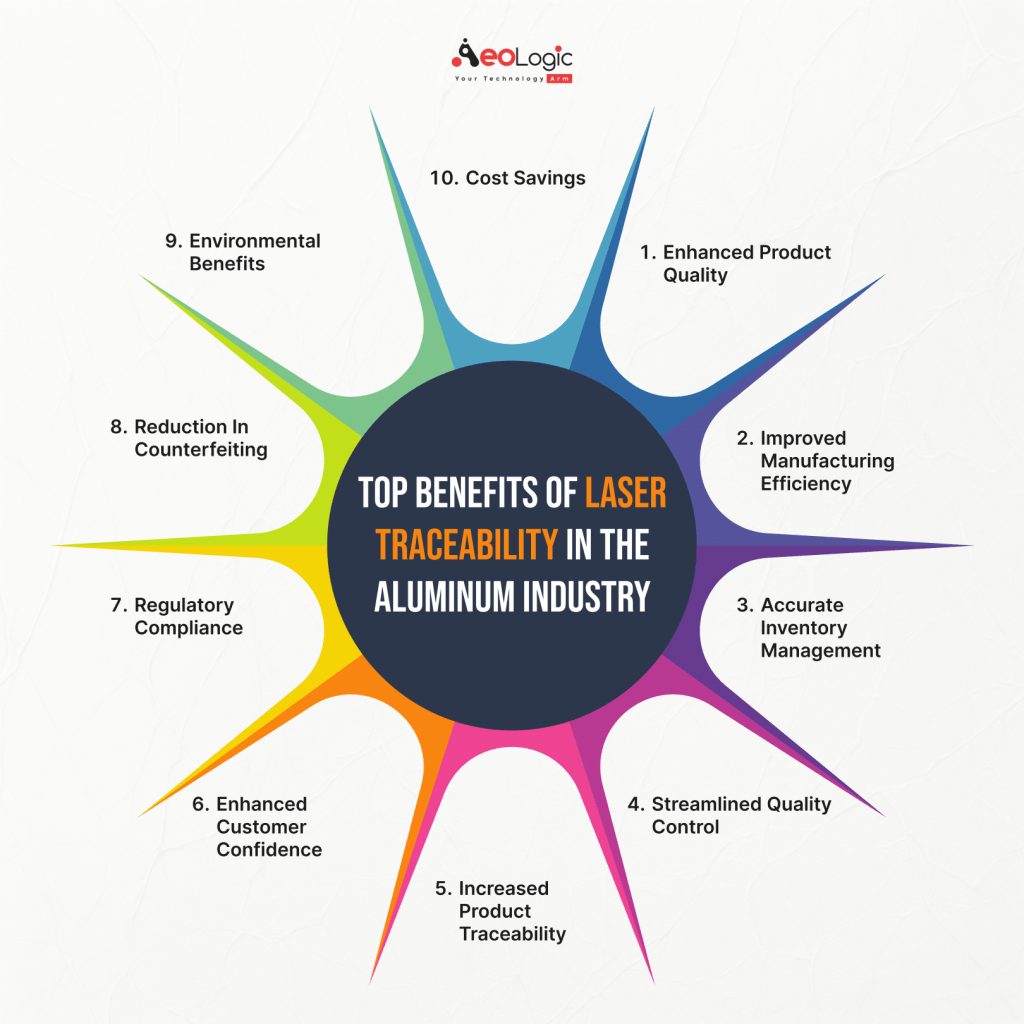

Top 10 Benefits of Laser Traceability in the Aluminum Industry

The Top 10 benefits of laser traceability in aluminum industry Going Where No Metal Has Gone Before. It’s changing the way aluminum manufacturers do everything, from improving product quality to enhancing sustainability.

1. Enhanced Product Quality

Laser traceability is an assurance of high quality aluminum products. Manufacturers can also track the materials used, production parameters, and quality control data by marking each product with unique identifiers. It helps in the detection and correction of any defects or problems thus improving product quality. For instance, element of defect is found in the above batch of aluminium sheets enables manufacturers to recognize the exact production run responsible for it, locate and solve it.

2. Improved Manufacturing Efficiency

The aluminum industry is all about efficiency, and laser traceability contributes to it in a great way. Manufacturers can optimize, achieve the shortest downtime, and minimize waste by precisely tracking materials and processes. This leads to reduced costs and shorter production cycles. For example, in the event that a machine in the production line shows signs of wear and tear, laser traceability data will activate preventive maintenance before any breakdown occurs hence continuous-production.

3. Accurate Inventory Management

Inventory control is difficult in any industry but critically important in aluminum manufacturing because of the costliness of the materials. In this regard, laser traceability facilitates the monitoring of raw materials and finished goods at any given time so that inventory is utilized efficiently. It helps eliminate stocks and cuts down on storage costs. This benefit is for example expressed in the ability of a manufacturer to determine with ease an overstocked material and adjust its order limits, hence avoiding unnecessary expenditure.

4. Streamlined Quality Control

Laser traceability makes quality control an integral part of aluminum production. Laser-marked identifiers are easily scanned allowing manufacturers to detect non-conforming products fast. This eases the correction of mistakes instantly and lowers the odds of sending faulty goods to customers. An example is an automatic Quality control alert avoidance of sub-par products if a laser-marked code shows a product dimension variance off the standard.

Also Read: The Role of Traceability in the Textile Industry

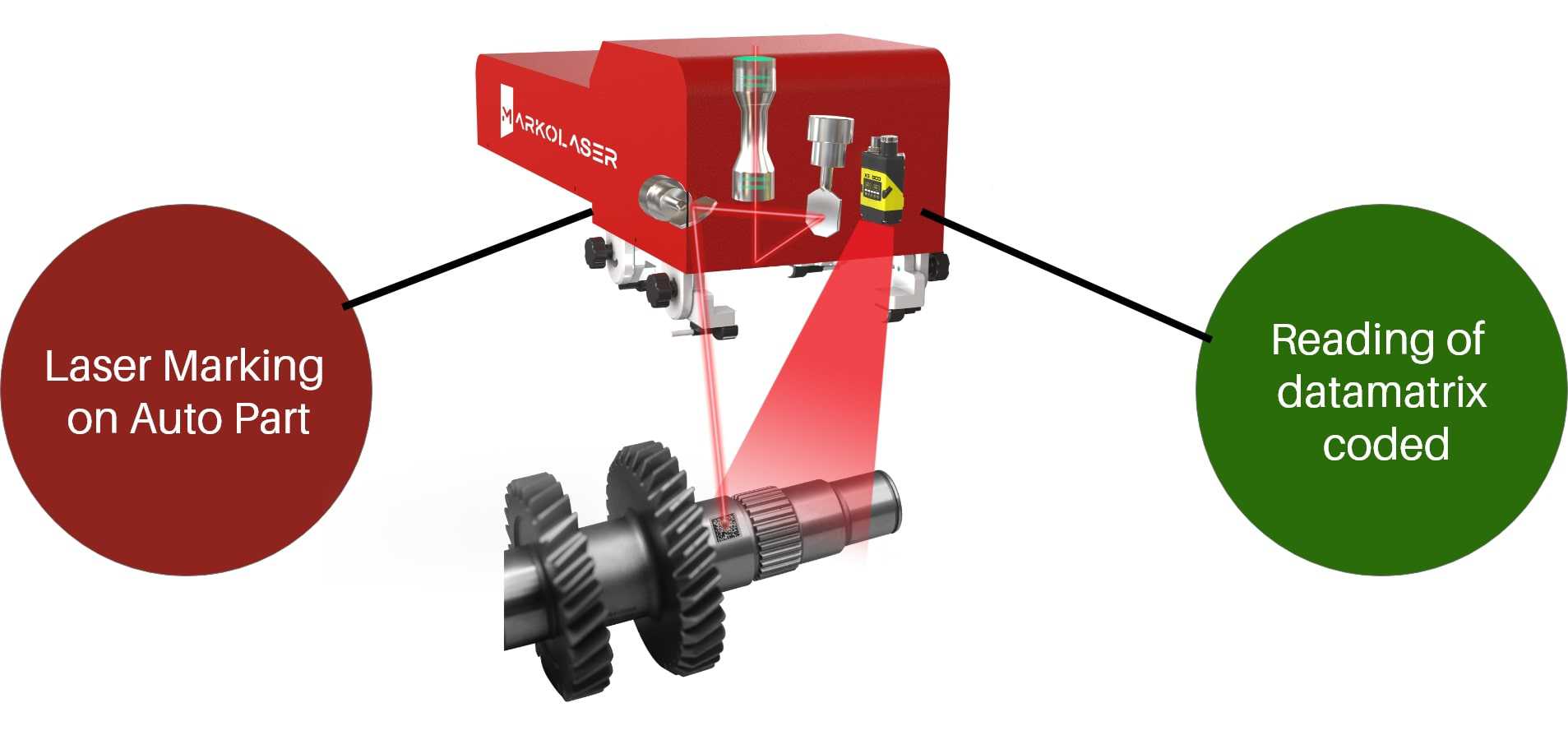

5. Increased Product Traceability

Laser traceability as the name suggests, it is very good in tracing of products. A unique code is printed to each aluminium product, which includes information such as origin, production date and other pertinent data. It also makes tracking the origin of any problems, initiating recalls if need be, and availing detailed product information to the customers. For example an unfilled order of aluminum component to a customer, the manufacturer can link the mistake to a particular production batch and improve on it.

Also Read: Sustainable Traceability in the Food Supply Chain

6. Enhanced Customer Confidence

The customers in the aluminum industry require transparency and reliability. Laser traceability provides both. With the knowledge that a manufacturer has adopted laser traceability, customers would have confidence in, quality and origin of products. In this regard, customers may develop liking for a given firm and look forward to become repeat customers. For instance, a customer can confirm that a product with laser traceability markings originates from an entity thereby trust the brand’s origin.

7. Regulatory Compliance

Aluminum industry is regulated against through various rules and standards. By keeping a full record of each products history, from its origin to the point of delivery, manufacturers are able to comply with these regulations through laser traceability. It serves as the groundwork for audits and keeps the company in good terms with regulators. For instance, when easuring audit is conducted by an industry regulator, a manufacturer can produce laser traceability records almost instantly and in turns demonstrates virtually immediate compliance.

8. Reduction in Counterfeiting

The issue of counterfeit products can also be very pronounced in the aluminium industry and this might interfere with the quality and ultimately brand name of a product. As a result, lasers make it difficult for counterfeiters to copy products accurately. The markings are a deterrent and help safeguard the manufacturers and consumers from counterfeit goods. For example, when the market is overwhelmed with fake aluminum products but consumers can be able to tell the real ones by examining them for laser traceability mark.

9. Environmental Benefits

The Aluminum Industry Looks Greener and Should We Grow Corn to Power Our Cars – Sustainability in the Aluminum Industry. As a result, laser traceability can be regarded as waste reduction efforts towards sustainability. Manufacturers can minimize their environmental footprint by improving on inventory management and quality control so as to ensure minimum quantities of aluminum go to waste. For instance, a manufacturer may use laser traceability data to minimize offcuts and optimize production processes so as to reduce material waste.

10. Cost Savings

In the end, laser traceability results in savings for aluminum manufacturers. It is the result of these efficiencies, waste reduction, and quality improvements that decrease production costs. Consequently, this can result in increased price competitiveness and strong profits. For example, using laser traceability, a manufacturer can identify a bottleneck in the production process and thereby adjust to make production more efficient and reduce cost of operation.

Also Read: Traceability Solutions for Food and Beverage Packaging Industry

Final Thoughts

To summarise, what laser traceability has for the aluminium manufactures declares a new trailer operation. There is no denying the benefits that range from better product quality and manufacturing efficiency to increased customer confidence and regulatory compliance. With future developments in the aluminum industry, adoption of laser traceability, it would not merely be an option but a requirement to remain in business and comply with the demands of clients and regulators.

To unlock the benefits of laser traceability in the aluminum industry, connect with Aeologic Technologies today and elevate your operations.