Imagine you are running a store. You have a lot of items to sell. How do you keep track of all these items? How do you know when something is about to run out? This is where barcode technology comes in. It’s like a silent helper, making sure everything is in order. This article will explore how barcode technology in stock control works like magic to keep stores running smoothly.

By The Numbers

Recent findings showcase the profound impact of barcode technology on stock control and management. Here are some highlights:

- Barcodes have been found to provide a tracking accuracy rate of 99%, which significantly benefits product management.

- Unfortunately, as of the latest data, around 46% of small businesses in the U.S. are still not utilizing barcodes or any tracking system for their inventory, hence missing out on the efficiency barcodes can bring.

- Companies leveraging barcode technology have witnessed increased efficiency in tracking inventory, reduced errors, improved organization, and enhanced data collection which all contribute to better inventory control.

- The use of barcode systems has been associated with quicker and more accurate inventory tracking, reduced time and labor required for manual data entry, thereby boosting efficiency and productivity in inventory management processes.

The numbers make it clear: utilizing barcode technology in stock control is a game changer for businesses aiming to streamline their inventory processes and enhance operational efficiency.

These statistics underline the importance of adopting barcode technology for effective stock control. The data demonstrates that through accurate tracking and automated data collection, barcode technology significantly uplifts the inventory management standard, making it a vital tool for modern-day businesses.

Related post for you! QR Code Attendance Tracking for Businesses and Classrooms

A Quick Look at Barcode Technology

Barcode technology has been around since 1974. It’s a simple idea. Each item gets a special code. When you scan the code, you get to know important details about the item. It’s like having a magic key to a treasure of information. This technology replaced the old way of writing down everything, which was slow and often had mistakes.

How Barcode Technology is Used in Stock Control

In the heart of a bustling store or a huge warehouse, barcode technology is like a silent, smart helper, keeping everything in check. Barcode technology in stock control is about making sure there’s enough stock, and knowing which items are flying off the shelves and which ones are not. Here’s how it works its magic:

Easy Peasy Scanning:

- Quick Check: A simple scan gives a world of info – price, quantity, and even the aisle where the item belongs.

- No More Guesswork: It takes the guesswork out of stock control. You know exactly what’s in stock and what’s not.

Real-Time Updates:

- Instant Info: As items are sold or restocked, barcode technology in stock control updates the data instantly.

- Always In The Know: You are always in the know about the stock levels, which is crucial for a smooth-running store.

Smart Reordering:

- Auto Reorder: Set a level and when the stock dips below it, barcode technology sends a reorder note. No more running out of stock!

- Better Deals: With clear data on what sells and what doesn’t, you can negotiate better deals with suppliers.

Save Time and Money:

- Less Time: No more spending hours on manual stock checking. The barcode does it faster and better.

- More Savings: Less time spent on stock control means more savings and more time to focus on growing your business.

Through these ways, barcode technology transforms stock control from a daunting task into a streamlined, easy-to-manage process. It’s like having a smart assistant who’s always on top of things, making sure your store is well-stocked and ready to meet the demands of the customers.

Also Read: RFID Vs Barcode: Why RFID is Better for Asset Tracking

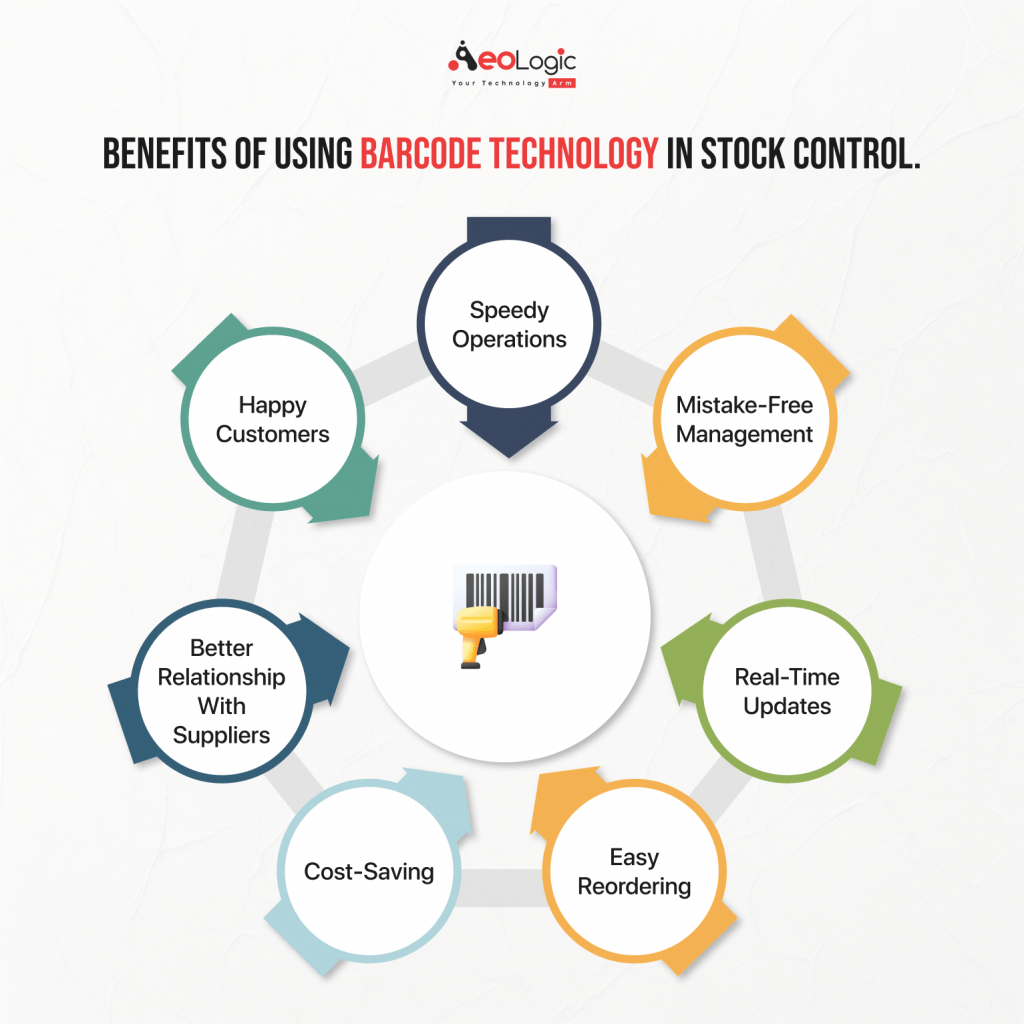

Top 7 Benefits of Using Barcode Technology in Stock Control

When you step into the realm of stock control with the aid of barcode technology, you open doors to a plethora of benefits. Here are the top 7 advantages of employing barcode technology in stock control:

1. Speedy Operations

The pace of operations is crucial in a retail or warehouse environment. Every second saved can translate to better service and increased profits. Barcode technology fuels this need for speed.

- Fast Scanning: Barcodes can be scanned quickly, making the process of checking items in and out speedy.

2. Mistake-Free Management:

Accuracy in stock control is not a luxury, but a necessity. A small error can lead to significant losses or dissatisfied customers. Barcode technology is a shield against such errors.

- Accuracy: The chances of errors drop significantly as barcode scanning is more accurate than manual entry.

3. Real-Time Updates:

In the dynamic environment of a store or warehouse, knowing the real-time status of stock is empowering. It’s like having a pulse on the heart of the business operations.

- Live Tracking: Know exactly what’s in stock at any given moment, helping in making informed decisions.

4. Easy Reordering:

Reordering stock shouldn’t be a game of guesswork. With barcode technology, it’s an orchestrated process that ensures continuity in availability.

- Automated Orders: Set up automatic reordering to ensure you never run out of stock.

5. Cost-Saving:

Financial prudence is the cornerstone of a successful business. Cutting down unnecessary expenses while maintaining efficiency is a tightrope that barcode technology helps in balancing.

- Less Labor: Barcode technology reduces the need for manual labor, saving money in the long run.

6. Better Relationship with Suppliers:

A smooth sailing relationship with suppliers is pivotal. Accurate and timely communication forms the bedrock of such relationships.

- Smooth Communication: Sharing accurate stock data with suppliers helps in maintaining a good relationship and smooth operations.

7. Happy Customers

The ultimate goal of any retail business is to keep the customers happy. A well-managed stock is synonymous with happy customers as they find what they need effortlessly.

- Well-Stocked Shelves: With better stock control, customers find what they need easily, leading to a satisfying shopping experience.

Incorporating barcode technology in stock control is like having a silent, efficient manager tirelessly working to ensure the wheels of inventory management keep turning smoothly.

Checkout our trending blog: Advantages of QR codes and Barcodes in Modern Business Technology

What Is Barcode Technology in Inventory Control?

Barcode technology is like a bridge that connects the physical items in a store to a digital system that tracks them. In inventory control, this technology is a godsend. Each item in the store gets a unique barcode, which is like its ID card. When this barcode is scanned, the system gets to know about the item—what it is, how much it costs, how many are left, and so on.

Now, when it comes to managing stock, barcode technology plays a huge part. Here’s how:

Quick Scans, Quick Updates:

- Instant Updates: When an item is sold, returned or received, a quick scan updates the system.

- Time-Saver: No need to spend hours updating stock info manually.

Accurate Stock Levels:

- Right Counts: Barcodes help in getting the stock count right, which is crucial for a store.

- Avoiding Errors: With manual counts, mistakes can happen. But barcodes keep errors at bay.

Smart Ordering:

- Knowing When to Order: With barcode technology in stock control, the system knows when it’s time to reorder items.

- Easy Orders: Reordering becomes a piece of cake, saving time and effort.

Barcode technology takes the guesswork out of inventory control. It’s like having a smart assistant that keeps an eye on stock, making sure everything is on track. And the beauty of it is, it all happens with just a simple scan. So, the next time you see a barcode, remember, it’s not just a bunch of lines and numbers, it’s a powerful tool keeping the store well-stocked and ready for business.

Do you Know? Benefits of RFID Asset Tracking in the Supply Chain

Final Words

Barcode technology is here to stay. With new tech like QR codes, it’s getting even better. It’s exciting to think how it will keep helping stores manage stock better.

So, the next time you shop, think about the silent helper working behind the scenes. The barcode technology in stock control is a simple yet powerful tool that makes shopping easy for you and managing stock easy for store owners.

So, if the wonders of barcode technology have piqued your interest, and you’re keen on elevating your stock control operations, reach out to us at Aeologic Technologies. With our expertise, let’s transform your inventory management into a seamless, efficient process, ready to tackle the challenges of modern retail.