The manufacturing industry is the industry that is going to explode in the future in terms of success. Nowadays, this industry has been staying ahead of other industries and setting a challenging mark for different sectors to reach in terms of global market size. Here are some stats mentioned below that define the authority of the manufacturing industry.

- Value added in the Manufacturing market is projected to be US$8.8tn in 2024.

- A compound annual growth rate of 1.15% is expected (CAGR 2024–2029).

- The value added per capita in the Manufacturing market is projected to amount to US$1,135.0 in 2024.

- The value-added margin in the Manufacturing market is projected to amount to 25% in 2024.

- Output in the Manufacturing market is projected to amount to US$35.1tn in 2024.

- A compound annual growth rate of 1.10% is expected (CAGR 2024–2029).

This industry can achieve more success if some problems can be fixed by implementing technologies. Still, many manufacturing industries follow conventional monitoring, tracking, detecting, data collection, etc that surely help them but at a low pace. IoT is the technology that can enhance the manufacturing industry’s present and future in a mind-blowing way. There are also several advanced manufacturers who have implemented this technology and surpassed their competitors.

Overview: How IoT is Revolutionizing the Manufacturing Industry

By improving operational efficiency, facilitating real-time data analysis, and encouraging predictive maintenance, IoT solutions have the potential to completely transform the industrial sector. Manufacturers may minimize downtime, optimize resource utilization, and keep a tight eye on manufacturing processes by linking machines, sensors, and gadgets. Better decision-making, enhanced supply chain management, and accelerated innovation are all made possible by this integrated ecosystem, which eventually boosts competitiveness and productivity in a market that is changing quickly.

The global IoT in Manufacturing Market size was valued at USD 50.0 billion in 2021 and is expected to grow at a CAGR of 11.9% from 2021 to 2026. The revenue forecast for 2026 is projected to reach $87.9 billion. These stats are going to improve with more implementation and awareness among manufacturers about this technology.

In this article, we will see the role of IoT solutions in the future of the manufacturing industry which nowadays seems too bright. We will also see some additional details like benefits, challenges, etc. After all meaningful discussion, we will end the discussion with a summed-up paragraph.

Also Read: Innovative Solutions for Manufacturing Industry in 2024

What are IoT Solutions in the Future of Manufacturing Industry?

Generally, IoT solutions refer to hardware and software combinations that let devices talk to the cloud and each other. Smart sensors for real-time monitoring, predictive analytics to foresee equipment breakdowns, and supply chain optimization for improved visibility are some of the IoT options for the manufacturing sector’s future.

While energy management systems assist cut costs by tracking use, connected machinery makes it easier for devices to communicate with one another. Overall IoT based solutions can enhance efficiency, productivity, and sustainability in the manufacturing sector. There are a few other benefits that we will see later in the upcoming paragraph.

Also Read: Best Software Solutions For Manufacturing Business Sector

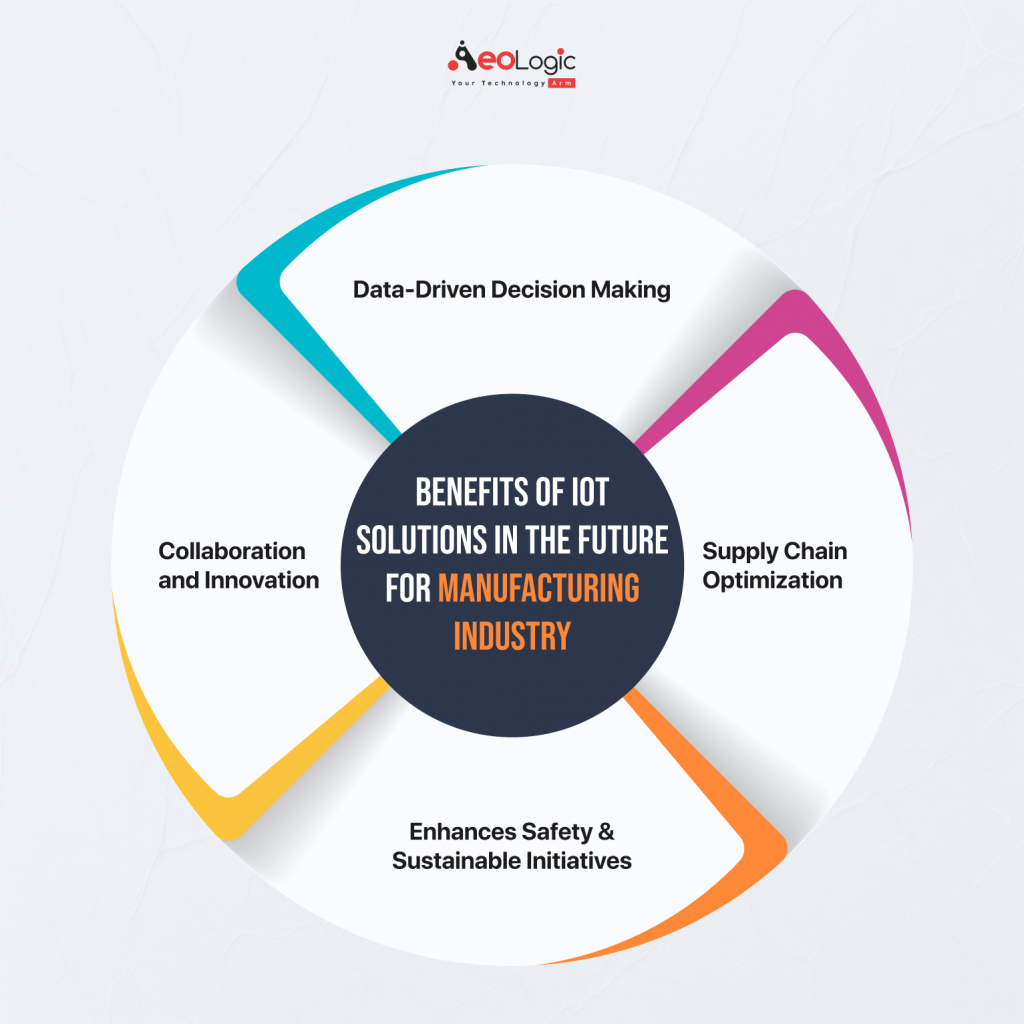

Benefits of IoT Solutions in the Future for Manufacturing Industry

There are many benefits of IoT solutions that can impact the future of the manufacturing industry in a positive way. Here are a few key benefits mentioned below.

Data-Driven Decision Making

Data-driven decision-making is an important benefit of IoT solutions that can enhance the future of the manufacturing industry. There are many manufacturers that use their common sense and prediction to make decisions and mostly they fail. Where with the solutions, manufacturers may collect enormous volumes of data for analysis. Making educated judgments, enhancing operations, and spotting trends are all aided by this data.

Supply Chain Optimization

This is also crucial to optimize the supply chain by using minimum resources to get the most results. IoT’s ability to track and monitor can enhance supply chain optimization for the manufacturing industry which could be a benefit overall. IoT solutions-based devices can better manage supply chains and track inventory levels, which reduces waste and improves resource allocation.

Enhances Safety

Safety is an important aspect of an organization as the manufacturing industry involves various machinery that could be risky for workers. There are a lot of workers around the world who lost their lives due to the unavailability of advanced safety tools. Workers’ health and safety monitoring via wearable IoT solutions-powered devices can improve workplace safety in real-time by warning of possible dangers.

Collaboration and Innovation

Humans and machines must foster better collaboration to increase productivity. The IoT’s ability to interconnect things or networks can play an important role in it. Through linked systems, IoT solutions promote increased cooperation between human operators and machines, spurring innovation in products and processes.

Sustainable Initiatives

Sustainability is a serious topic to talk about as there are many manufacturing industries that cause a lot of pollution through their processes. This occurs mostly due to not recording data on the emission of pollution that the manufacturers are not aware of. Where manufacturers may adopt more environmentally friendly procedures and comply with regulations by using IoT solutions to track energy use and emissions.

Also Read: The Role of IoT in Predictive Maintenance for Manufacturing Operations

Challenges with the IoT Solutions in the Future of Manufacturing Industry

We have seen a lot of benefits but there are a few challenges too that could interrupt the implementation of IoT solutions in the future for the manufacturing industry. Here are a few mentioned below.

- IoT solutions mostly depend on internet connectivity so any interruption in the internet could result in the overall calculation. So this could be a challenge for bad connectivity regions.

- Initial implementation cost can be a topic to worry for many small manufacturers. It takes too much to implement IoT sensors, software, solutions, etc.

- Employees may object to the operational and cultural changes that are frequently necessary for a business to adopt IoT technologies. So management change can be another challenging thing in the future.

Also Read: The Importance of Traceability in Manufacturing: An Overview

Final Words

IoT-powered solutions look promising at the moment and can increase productivity, better decision-making, and provide more flexibility, which could revolutionize the manufacturing sector in the future. IoT enables real-time data collection and analysis, which gives manufacturers the ability to continuously innovate, optimize processes, and cut costs.

Manufacturers must integrate IoT technology strategically as the industry develops, guaranteeing scalability and interoperability while encouraging an innovative and flexible culture. There could be a few challenges too but by overcoming these challenges, manufacturing organizations may fully utilize IoT, opening the door to a manufacturing environment that is more competitive, sustainable, and efficient in the years to come.

Choose Aeologic as an expert solutions provider to help you navigate these challenges and unlock the full potential of IoT for your business.