The manufacturing industry generally refers to the process of creating or producing items using machinery, tools, labor, equipment, and chemical or biological formulation or processing. It is the core of the economy’s secondary sector. This industry is vital in various terms for providing daily life products and for global development in terms of economy too. The global manufacturing industry is projected to be worth $35.1 trillion in 2024, with a compound annual growth rate (CAGR) of 1.10% from 2024 to 2029. Here are some other manufacturing industry projections for 2024.

As we can see there are a lot of things around us that are manufactured via different materials. The manufacturing process consists of various stages and many stages produce a lot of harmful material and this is a serious concern. Manufacturing should be done in a way that offers sustainable practices and quality products. However, this is not possible to achieve via conventional methods of manufacturing. This needs something modern and advanced that can control the adverse environmental effects during manufacturing and establish sustainable practices. Here are some stats that show how badly industrial pollutants affect the world.

-

- Every second 310 Kg of toxic chemicals are released into our air, land, and water by industrial facilities around the world.

-

- This amounts to approximately 10 million tons (over 21 billion pounds) of toxic chemicals released into our environment by industries each year.

-

- Of these, over 2 million tons (over 4.5 billion pounds) per year are recognized carcinogens. This amounts to about 65 Kg each second.

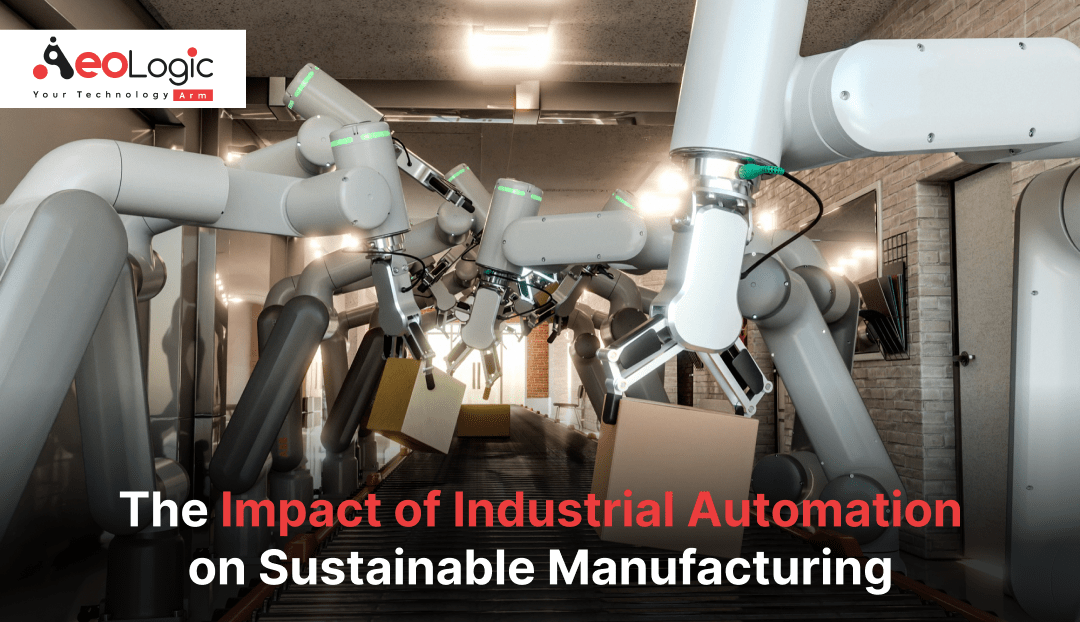

In a world full of technologies, tools, and much more, the best automation solution has the potential to make an impact on the manufacturing industry to reduce bad environmental impacts. The industrial automation market is expected to grow at a compound annual growth rate (CAGR) of around nine percent until 2025. In 2025, the size of the global industrial automation market should reach roughly 265 billion U.S. dollars.

Industrial automation creates sustainable production by increasing operations efficiency and reducing waste with modern technologies like robotics and the Internet of Things. These systems minimize emissions and waste production by optimizing resource use, cutting energy use, and guaranteeing accurate material management. Automation supports the circular economy’s tenets and encourages sustainable supply chain practices by enabling flexible manufacturing processes and data-driven decision-making. It also develops a workforce that is proficient in cutting-edge technology.

In this article, we will see the role of industrial automation in achieving sustainable manufacturing. We will also go through additional details like benefits, challenges, etc, and end the discussion with some final words.

What Does Industrial Automation Refer to for Sustainable Manufacturing?

Automation can be defined as a system that performs tasks automatically without the interference of human beings. Many forms of automation are used in different industries such as robots, automated counting machines, etc.

Industrial automation for sustainable manufacturing generally refers to the use of cutting-edge technology like robotics and control systems to increase production efficiency while reducing environmental impact. One of the key benefits of implementing industrial automation in production lines is the ability to streamline operations through accurate material management. Through accurate material management, energy-efficient processes, and data integration for well-informed decision-making, it maximizes resource consumption. It affects the workforce by requiring the development of sophisticated technology skills, which eventually results in a workforce that is knowledgeable and committed to sustainability.

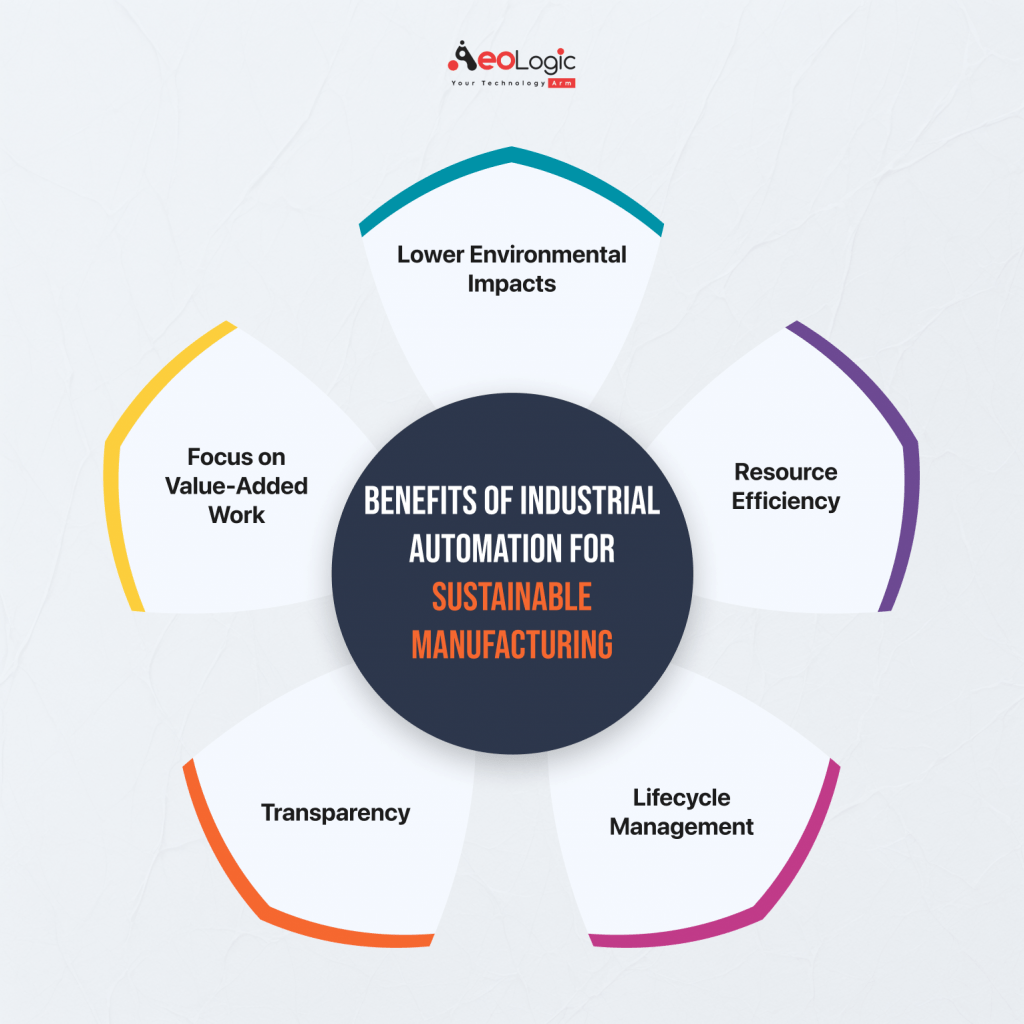

Benefits of Industrial Automation for Sustainable Manufacturing

There are a lot of benefits of industrial automation on sustainable manufacturing as here are a few key benefits mentioned below.

Lower Environmental Impacts

There are many products like tires, tubes, and plastic products that cause the emission of harmful gas while manufacturing. This is not sustainable for nature as well as human beings. With industrial automation, production-related greenhouse gas emissions can be greatly reduced by streamlining activities. Automation supports recycling efforts by efficiently tracking and managing garbage.

Resource Efficiency

Resource efficiency is very important as it is crucial to utilize less amount of resources to get high-quality products. This does not let us waste extra products or resources. Through improved quality assurance and precise control, industrial automation can reduce material waste, resulting in less scrap and rework. Through real-time process monitoring and adjustment, automated systems minimize waste and maximize energy utilization. This overall increases resource efficiency.

Also Read: The Role of RFID Technology in Industrial Automation

Lifecycle Management

Lifecycle management of products and scraps is very important as this helps to reduce waste materials. Without having proper tools or techniques, it is not possible to track the lifecycle of materials that do not properly enable lifecycle management. Better planning for recycling or end-of-life disposal is made possible by automated systems that can track product life cycles.

Transparency

Sustainability cannot be achieved without having insights and information about the manufacturing industry or manufacturing process. Manual gathering of information cannot get accurate insights. With industrial automation, it is possible to improve data collection which enables businesses to provide more accurate reports on compliance and sustainability parameters.

Focus on Value-Added Work

Only tools or techniques cannot help too much to gain sustainable manufacturing as workers should also move towards sustainable ways and parameters to establish sustainability. With the implementation of industrial automation, workers can take on more strategic responsibilities, which will support sustainability and innovation projects.

Related Blog: Role of Industrial Automation in Product Traceability

Challenges in Industrial Automation for Sustainable Manufacturing

We have seen a lot of benefits of industrial automation for sustainable manufacturing. But there could be some potential challenges too as there are a few mentioned below.

-

- Automated systems are susceptible to malfunctions, which could cause output to be disrupted. So reliability on technology can be a challenging factor too.

-

- The overall sustainability aims may be challenged by the environmental effects of automated technology production and disposal as resource consumption could be another challenge.

-

- Management change can be a problem for manufacturing organizations as workers could resist change brought about by automation.

Also Read: Transform Your Business With Custom Software Automation

Final Words

Industrial automation is essential to the advancement of sustainable production because it increases productivity, decreases waste, and lessens its impact on the environment. Businesses may enhance product quality, optimize resource consumption, and promote circular economy principles by integrating cutting-edge technologies.

To get these mentioned benefits, there are many challenges that need to be navigated. Manufacturing organizations can use industrial automation to increase productivity and accomplish sustainability objectives by proactively tackling these challenges and encouraging an innovative culture. This will ultimately help the industrial sector have a more sustainable future.

Connect with Aeologic Technologies for the best solutions to overcome these challenges and achieve sustainable manufacturing goals.