The manufacturing industry is one of the growing industries of all time as there are a lot of manufacturers around the globe. This industry has great value in the global market as there are few recent stats mentioned below that could be able to provide you with more vision about this industry.

-

- Value added in the Manufacturing market is projected to amount to US$8.8tn in 2024.

-

- A compound annual growth rate of 1.15% is expected (CAGR 2024–2029).

-

- The value added per capita in the Manufacturing market is projected to amount to US$1,135.0 in 2024.

-

- The value-added margin in the Manufacturing market is projected to amount to 25% in 2024.

-

- Output in the Manufacturing market is projected to amount to US$35.1tn in 2024.

-

- A compound annual growth rate of 1.10% is expected (CAGR 2024–2029).

-

- The output per enterprise in the Manufacturing market is projected to amount to US$6.4m in 2024.

-

- The manufacturing intensity in the Manufacturing market is projected to amount to 36.6% in 2024.

Since this industry is important for the global market as well as for people this industry provides things that we use in our daily lives. However, the conventional method of manufacturing processes carries many issues that are not efficient in balancing the demand and production in today’s world. There are issues like vast amounts of data management and storing, security, bad inventory management, time-consuming repetitive processes, etc that do not let this industry grow. Many manufacturing organizations have adapted tools or technologies that have solved their issues but still, there is a lot to implement. Cloud computing is one of the technologies among all the technologies that have the potential to revolutionize manufacturing processes in various ways.

Overview

Cloud computing technology has been used in most industries or sectors at a rapid pace for the past few years. The global cloud computing market has significantly increased to $446.51 billion in 2022 and garnered $500 billion in 2023. It is expected to surpass $1 trillion by 2028 and $1.6 trillion by 2030.

As mentioned earlier cloud computing has been implemented in many manufacturing industries as the global Cloud Computing in Manufacturing Market size was valued at USD 59.80 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 18.2% during the forecast period, reaching a value of USD 198.47 billion by 2030.

In this article, we will take a brief look at the impact of cloud computing on manufacturing processes with some additional details like benefits, challenges, etc. Hope that this article will be able to provide you with clear information on the topic mentioned.

The Role of Cloud Computing For Manufacturing

Cloud computing is a technology that promotes productivity and creativity by enabling users to exchange files, databases, and applications over the Internet. In manufacturing, cloud computing, particularly through Cloud-Native Applications in Manufacturing, refers to exchanging and utilizing production data, their availability, and much more by leveraging computer and software power. Manufacturing processes directly benefit as their efficiency increases with this technology. Error rates reduce, ROI increases, and aspects like security and data management are revolutionized.

How Can Cloud Computing Impact The Manufacturing Processes?

Cloud computing can make an impact on the manufacturing industry and manufacturing processes by various means as manufacturers can reduce downtime and maximize output with the help of cloud computing. It lessens interruptions and improves forecasts by quickly locating and fixing problems. Delivery dates can then be more readily met, production can rise, and quality can improve. There are many other benefits too that we will see later in the upcoming paragraph.

Also Read: Top Benefits of Cloud Computing Technology for Ecommerce Stores

Benefits Of Cloud Computing on Manufacturing Processes

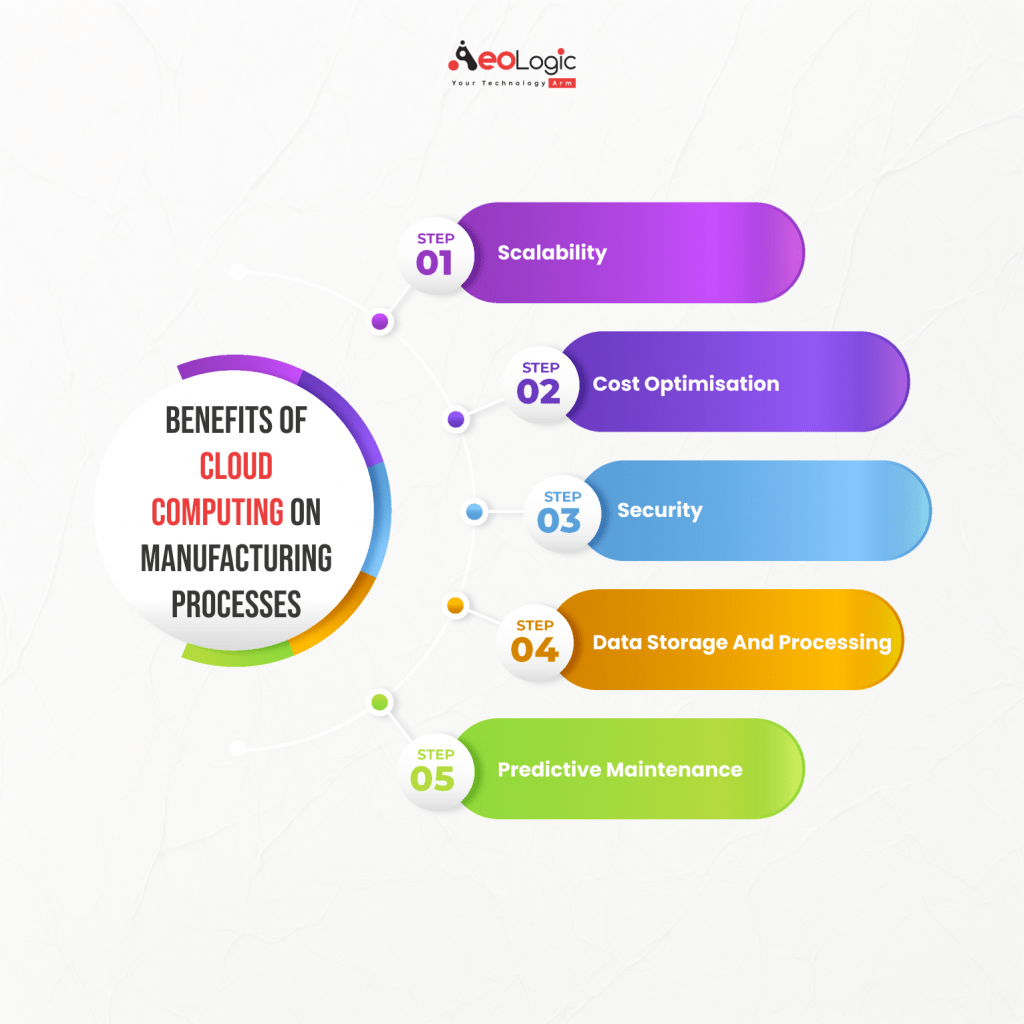

There are many benefits of cloud computing for the manufacturing processes and key benefits are mentioned below.

1. Scalability

Cloud solutions are easily scalable to support short-term demand variations and long-term corporate expansion. Due to overstretching in the manufacturing process, even little disturbances might result in significant losses. However, with cloud computing technology, scalability is generally enhanced so that it does not cause too much damage and disruption.

2. Cost Optimization

Cost optimization is very vital in the manufacturing industry as sometimes it gets disturbed due to extra expenses. Manufacturers no longer have to overprovision their IT infrastructure to meet peak demand thanks to cloud computing. Alternatively, they can save money by not having to buy, install, configure, or maintain on-premises infrastructure because they can provision the necessary capacity as needed.

3. Security

Security is very important, especially when it comes to protecting sensitive data in the banking industry. Any breach in security can cause significant damage to a company in various ways. That’s why Cloud-Based Fraud Prevention Solutions for the Banking Industry are essential. Cloud providers like AWS, GCP, and Azure offer robust security measures, including encryption, multi-factor authentication, and constant monitoring. Unlike on-premises solutions, cloud software receives regular updates and patches to address security vulnerabilities, ensuring that external interference in the manufacturing process or the company’s system is minimized.

4. Data Storage and Processing

Manufacturing processes consist of vast amounts of data that are complex to manage and store. Large volumes of data can be processed and stored via cloud computing without the need to purchase sophisticated internal infrastructure. It is necessary to integrate Industry technologies such as machine learning, artificial intelligence, and connectivity for the Industrial Internet of Things into practice.

5. Predictive Maintenance

Equipment condition monitoring can be done remotely and in real-time with cloud-based predictive maintenance tools. Machine learning algorithms can utilize this data to identify early indicators of equipment breakdown and automatically schedule maintenance. It increases the overall effectiveness of the equipment, reduces downtime, and optimizes maintenance schedules.

Also Read: How is the Cloud Computing Shaping Healthcare Industry?

Challenges With Cloud Computing on Manufacturing Processes

We have seen a lot of pros of cloud computing for the manufacturing processes but there are a few challenges too. Here are a few challenges mentioned below.

-

- Cloud computing is a very recent technology so like other technologies, its initial cost of implementation is also high. So it could be a challenge for many small manufacturers.

-

- One of the major challenges with cloud computing is the internet as it needs proper internet access to perform tasks. If your area doesn’t have a proper internet connection then you can’t access cloud computing.

-

- It is very hard to find cloud computing professionals as many education organizations are not very aware of this technology.

Final Words

The manufacturing sector can benefit greatly from cloud computing, especially when it comes to data integration, artificial intelligence, and process optimization. The significance of cloud computing in manufacturing is only going to grow as long as firms embrace digital transformation. We have also seen various benefits and challenges but challenges could be overcome with the development of this technology. Overall this technology has the capability or potential to revolutionize manufacturing processes in various ways.

For those comfortable with moving their production to the cloud transformative capabilities of cloud computing Aeologic Technologies is the ideal provider. Reach out to us and start on the path of creativity and growth, suitably customized to which stage your business is.

I’m Deepika Pandey, an SEO strategist and content writer with 6+ years of experience. I create SEO-friendly content that drives traffic and engages readers. I combine data insights with creativity to help businesses grow their online presence effectively.