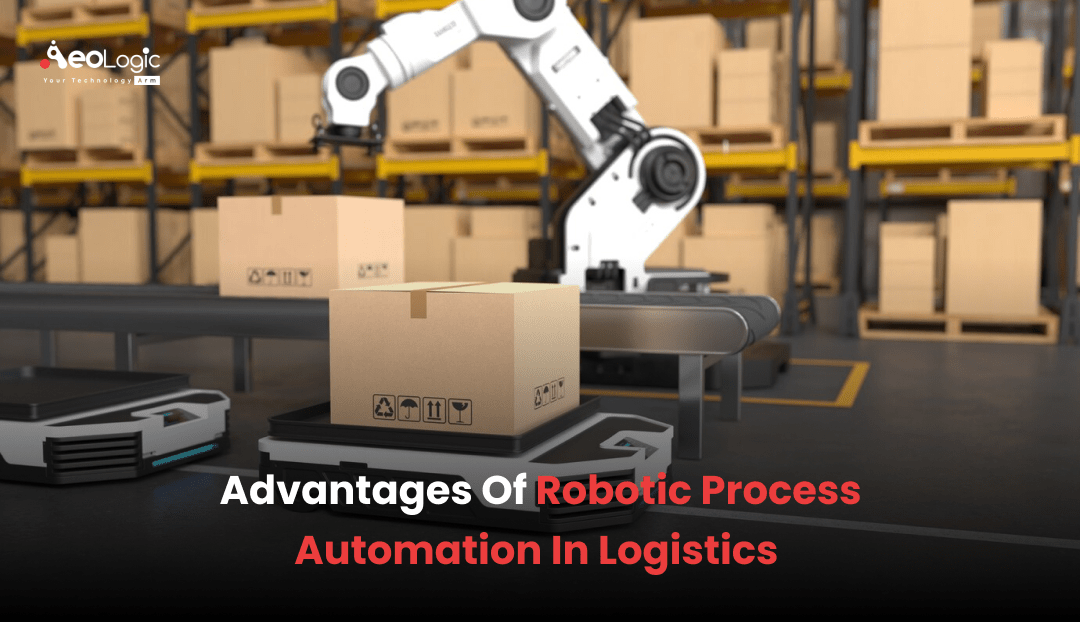

In every industry, there is a process of managing how resources are acquired, stored, and transported to their final destination that is called the logistics process. This involves a lot of processes at every stage that need to operate properly. From the initial to the final preparation of products needs to be managed efficiently so that quality does not degrade. There are many repetitive processes that take hard labor and time to perform and in that term, complex processes remain to complete. There are also high chances of error while processing tasks manually which could affect the industry’s productivity and efficiency.

To tackle all the above-mentioned problems, it needs something to involve the industries in the logistics process. Many industries have taken the help of technology to tackle all these issues and mostly succeeded. Robotic process automation is one of the technologies that can resolve these issues in the logistics process by offering many beneficial aspects too. There is nothing new about this technology as it has developed very before and also settled a good marker size.

The global Robotic Process Automation (RPA) Market size was valued at USD 6.2 billion in 2023 and is predicted to reach USD 32.4 billion by 2030 with a CAGR of 27.0% from 2024-2030.

In this article, we will study the details about the importance of robotic process automation in logistics and also see many other details like advantages, and key challenges lastly, we conclude on this technology in logistics processes.

What does Robotic Process Automation Refer To?

Software technology known as robotic process automation (RPA) makes it simple to create, implement, and oversee software robots that mimic human behavior when dealing with software and digital systems. In the logistics processes, robotic process automation software can prove very vital and efficient; it can enable the smooth flow of Goods and Services between the organization and the suppliers. This is a software-based technology that can ease the human labor in an industry and make processes accurate, fast, and efficient to perform.

Also Read: Benefits of Implementing RPA in Banking and Financial Industry

How Robotic Process Automation Beneficial in Logistics?

The logistics process is not related to the manufacturing industry but in every type of industry, some processes perform from initial to final, and all could be involved in the logistics process. With robotic process automation, companies can get benefits in various ways as businesses can use RPA automation to automate data recording by extracting important information from emails and using it for customer profiling, order management, payment processing, and progress monitoring. There are many other key advantages of RPA in logistics that we will see later in detail.

Advantages of Robotic Process Automation Beneficial in Logistics

There are many advantages of robotic process automation in logistics as there are a few advantages mentioned below.

Satisfied Clients

In logistics, robotic automation processes can enable automatic control and speedy order and delivery processing. Customers can therefore easily place more orders and get them sooner than before. It fulfills the expectations and meets the needs of even the pickiest ones with the aid of RPA software. This overall satisfied the clients and increased trust in the company.

Increased Efficiency

There are many repetitive and time-consuming processes in an industry like data entry, invoice processing, shipment tracking, and order management, that robotic process automation can automate and streamline. RPA software-based systems may operate continuously without needing breaks or vacations, which reduces manual errors and processing times, improves overall operational performance, and increases efficiency and productivity in logistics operations.

Enhanced Accuracy

RPA minimizes the possibility of human error by ensuring high accuracy in data processing. This is crucial for the logistics sector, as operations like inventory control, shipment monitoring, and regulatory compliance depend on precision. This totally improves the error rate in logistics processes.

Better Inventory Control

Inventory management is a crucial aspect in an industry but it is quite difficult to develop better inventory. With robotic process automation, it would help to make projections on how fast our product can be finished, studying the employee behavior, which also helps to make projections, and it would also be the process of sending automatic notifications to the financial responsible when there are not enough materials or products.

Accuracy and Quality

RPA provides improved services to processes with a high risk of human mistake, boosting accuracy. Robots are dependable and consistent, and they do not complain when asked to labour ceaselessly. They also significantly minimise the number of reworks and increase the product quality. The best aspect is that robots strictly adhere to all laws, resulting in 100% accuracy in process results. Let’s not forget what makes this bargain even sweeter: the rapid adoption of this technology. RPA optimises capabilities, which increases organisational capacity.

Also Read: Why Robotic Process Automation is the Future of Business

Challenges with Robotic Process Automation in Logistics

We have seen many advantages of robotic process automation in logistics but there are a few challenges too. Here are a few challenges mentioned below.

- Integration with the existing system is a challenge in implementing RPA for logistics as the existing system contains various protocols, technology, etc. So it could be concerning for many.

- Scalability can be a challenge as some automated processes change or must be adjusted for regulatory updates. At this point, RPA systems built to support smaller capacities may start underperforming.

- RPA needs long-term maintenance that costs too much. Its initial implementation cost is also too much which is concerning for many industries.

Checkout our Trending Blog: Top 10 Guidelines for Efficient Robotic Process Automation

Conclusion

Robotic process automation reduces carrying costs by streamlining procurement, minimizing mistakes, and optimizing inventory levels in logistics operations. Response times and customer satisfaction are enhanced with automated customer support. Moreover, RPA guarantees compliance, improves the effectiveness of logistics, and offers real-time data for improved decision-making. Overall, Robotic process automation has the potential to evolve the logistics operation that every industry should implement.

I’m Deepika Pandey, an SEO strategist and content writer with 6+ years of experience. I create SEO-friendly content that drives traffic and engages readers. I combine data insights with creativity to help businesses grow their online presence effectively.